Rollers

Rollers for bulk handling

Rollers, very often, represent a high investment in the overall requirements of the project design of a belt conveyor installation.

The choice of high quality rollers that guarantee an adequate working life with the result that equipment may function without the business of the plant being interrupted.

It has been well proven that considering the overall economies in today’s modern conveyors, their life and efficiency depends to a great deal on the choice of quality rollers, accurately manufactured using highly selected materials.

Of particular importance in the search for efficiency is the sealing system that protects the roller bearings.

Rulmeca, keenly aware of this requirement, has subjected and examined their design of manufactured rollers to severe laboratory tests.

Numerous examples of plant and equipment used in material handling, all over the world, operating in the most severe environmental conditions, have used Rulmeca rollers of various types for many years.

Rollers produced by Rulmeca are manufactured according to all known national and international standards: ISO, UNI, DIN, AFNOR, FEM, BS, JIS, SANS and CEMA.

Products list

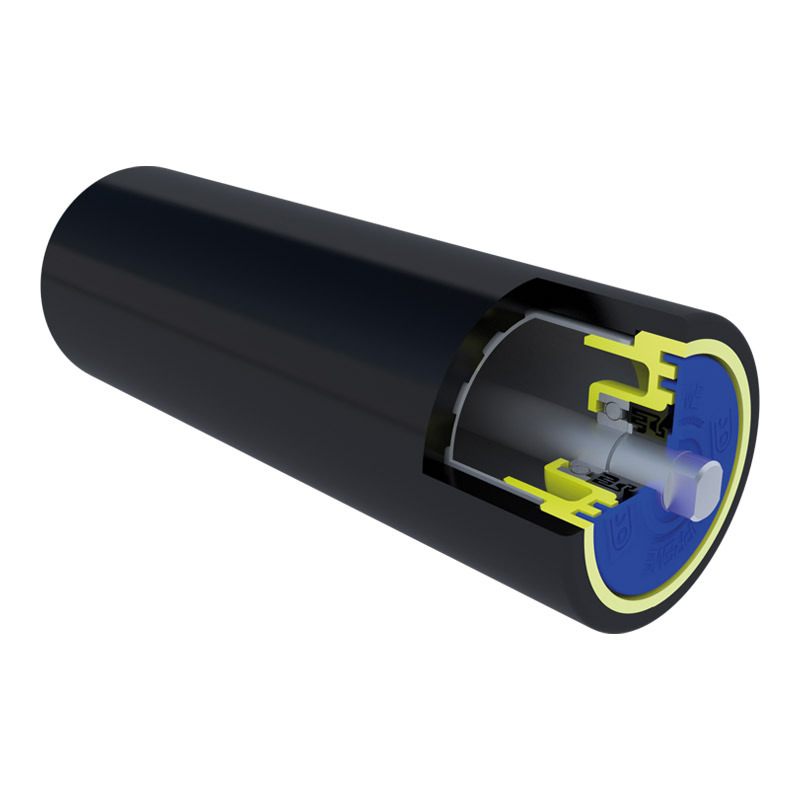

PSV

- Top quality heavy duty roller with hermetic sealing system.

- Robust, precise, welded construction, shafts ø 20, 25, 30, 40.

- Very long life, even in heavy and dirty working conditions.

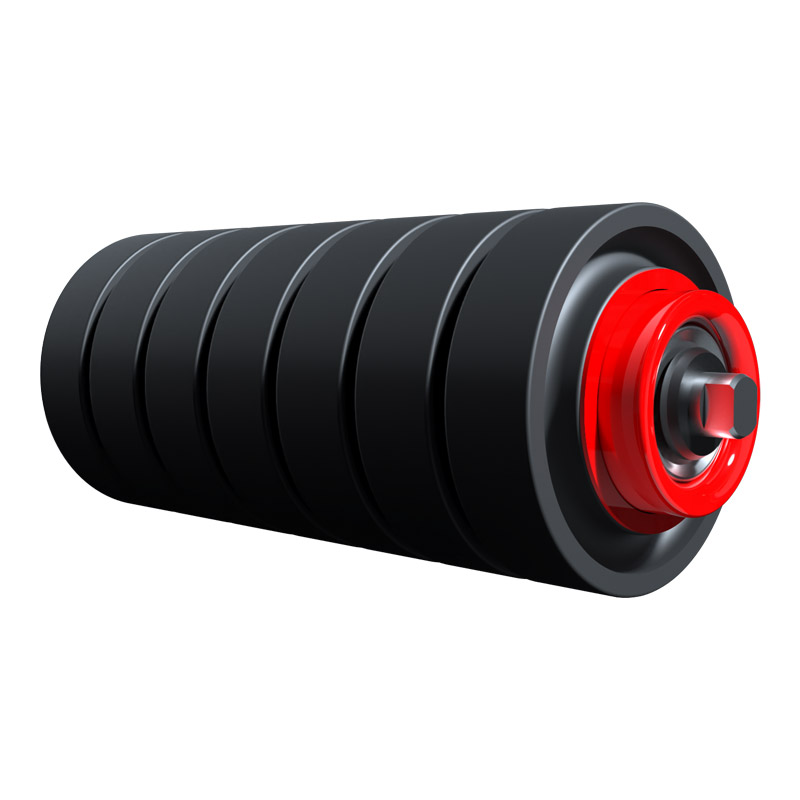

Impact Rollers with Rubber Rings

- Higher quality rubber rings, respect competitors.

- Solid rubber rings fixation by high steel stop ring, welded to the shell.

- Highly efficient & hermetic sealing system → long life roller.

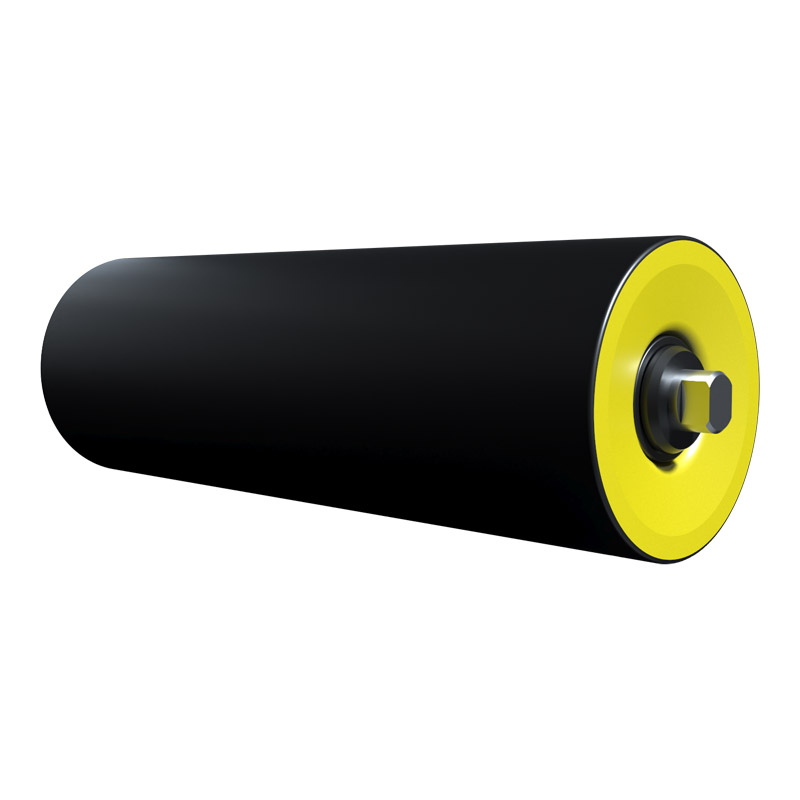

Return Rollers with Rubber Rings

- Higher quality rubber rings, respect competitors.

- Solid rubber rings fixation by outer steel stop ring welded and hard pvc central distance rings.

- Highly efficient & hermetic sealing system → long life roller.

Return self-cleaning rollers with helical rubber rings

- Higher quality rubber rings, respect competitors.

- Solid rubber rings fixation by outer steel stop ring welded and hard pvc central distance rings.

- Highly efficient & hermetic sealing system → long life roller.

Guide Rollers

- Very solid high wall thickness, resistant to belt edge wear.

- Top closed tight shell + smooth rotation due to contacless seals.

- Standard + all requested executions (ex, for pipe conv.).

Belt Tracking Rollers

- Self centring highly efficient heavy return roller / belt friendly.

- Rugged mechanical construction / thick and strong rubber lagging.

- All standard & custom dimensions possible.

MPS

- Precise, robust welded roller, with ø15mm shaft, for medium duty.

- Cost saving solution, where not needing shaft ø20mm.

- Tight & compact sealing system, also for outdoor & dirty environment.

RTL

- Anticorrosion polymer housings, with ø15mm shaft, for light duty

- Highly cost saving solution, also with stainless steel options (tube, shaft, bearings)

- Tight & compact sealing system, also for outdoor & aggressive environment

DSK Rollers Extra Heavy Duty

- Extra heavy duty rugged roller.

- Forged or massive, welded bearing housings, shafts ø 40, 50, 60, 80, 90.

- Multi stage labyrinth contacless seals – low running resistance.

Supreme

- Anticorrosion polymer roller (housings & tube) for heavy duty.

- Shafts ø25-30-40, hermetic or contactless seals options.

- Extra low noise rotation due to outer turned hdpe shell.

TOP

- Anticorrosion polymer roller (housings & tube) for medium-heavy duty.

- Shafts ø20-25, hermetic or contacless seals options.

- Extra light weight, low noise level due to outer hdpe shell.

Series PL

- Anticorrosion full polymer roller for medium duty (salt & acid conveyors).

- Shafts ø20, polymer slotted bush, contacless, low running resistance.

- Extra light weight, low noise level due to outer pvc shell.

Low Noise Rollers

- Supreme standard rollers, or psv, top, mps, dsk with machined lathe turned shell.

- Option with internal dumper (for large rollers), or rubber lagged turned shell.

- Rollers equipped with low noise bearings for electrical motors.

PDF Catalog

PDF Catalog