Ultrasync Belts

For positive drive and synchronous conveying

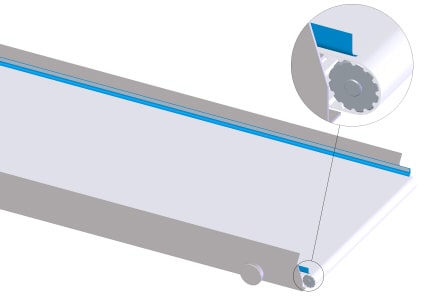

Ultrasync Belts are fabric based positive drive belts, combining the advantages and characteristics of synthetic conveyor belts and positive drive belts like modular and timing belts.

| Applications: | Benefits: | |

|

|

Product Range

Our Ultrasync Belts are synchronous and driven by a standard T10 sprocket with a pitch of 10 mm. Available up to 1000 mm wide.

Ultrasync Benefits & Features per Industry Application:

Food industry:

- Compliance with Food Grade standards (EC 1935/2004, EU 10/2011, FDA)

- Non-stick profiles

- Light blue colour for detection of contamination

- Seal edge protection possible

Hygiene paper production:

- Low friction fabric for vacuum lanes

- High speeds – up to 450 m/min

- Optimum grip covers for positioning

- High tensile strength even with vacuum holes due to fabric base

Tyre building:

- Synchronised and precise positioning

- High release properties

- Optimum grip covers for positioning

- Less downtime – splicing on site

TPU – Thermoplastic polyurethane

A durable and easy clean plastic. The thermoplastic properties allow for an embossed belt surface as well as welded accessories.

For slip free conveying (even if the belt / conveyor is polluted with fat, moisture, dough or flour).

Industries / applications:

- Food Industry

- Meat, poultry & fish: in portioning equipment and slicers

- Bakery

TPE – Thermoplastic polyester

This belt offers excellent chemical resistance.

Industries / applications:

- Tobacco Industry

- Other applications too, where specific chemical resistance is needed

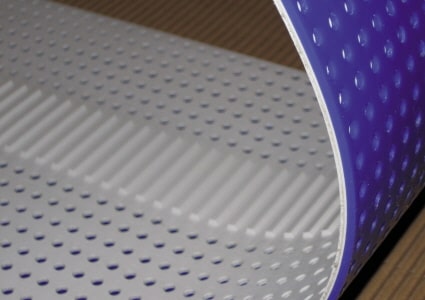

Silicone

- Non-stick and positive drive

- Often perforated

Often used in combination with vacuum to keep a product in place. This in combination with the positive drive of the belt enables the user to know exactly where the product is at all times.

Industries / applications:

- Used in packaging equipment

- Hygiene Industry (diaper production for instance)

- High speed gluing stations

- In applications where high friction and non stick properties are needed

Fabric

Polyamid fabric on topside and bottom side or combination

This low friction fabric allows for:

- Product accumulation

- Sideway on and off-loading of products

Industries / Applications:

- Tyre Industry

- Packaging Industry