Special (Customized) Belts

In addition to the more common belts we keep in stock, we also have a vast range of custom made belt options available for clients to choose from.

With our Engineered Belts we pay special attention to the individual requirements of your plant or machinery. Even extremes of strength, exact dimensional tolerances and surface quality specification can be catered for using our modern fabrication techniques.

Examples

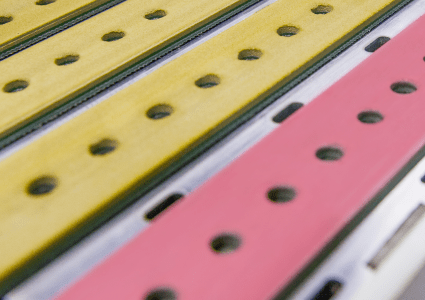

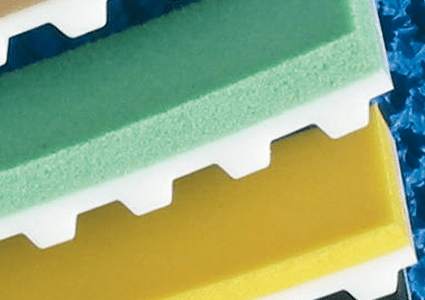

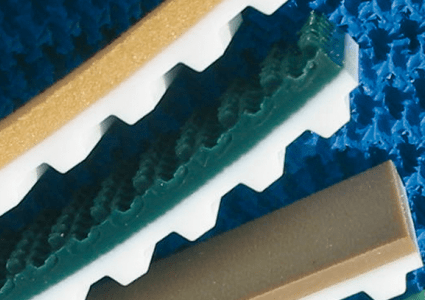

Schiki Belting Customized Belts, assorted with different types of extra cover materials, are designed to meet customer specifications.

We understand your processes and equipment and can provide the right solution for your business.

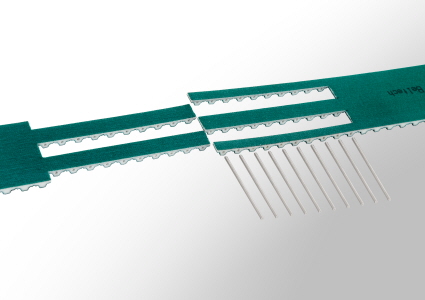

Feeder Belts

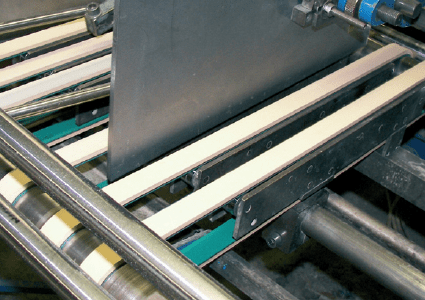

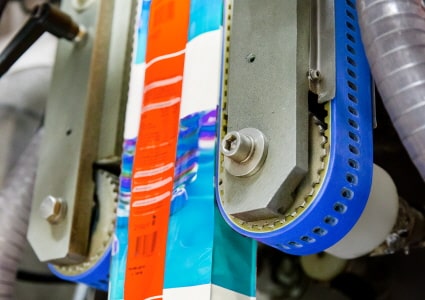

Our Feeder Belts are used in folder gluer machines in the Corrugated Industry to feed the box dies.

Our cover, with its exceptional friction and wear-resistance, gives Feeder Belts excellent performance and a long service life.

In addition, our food-approved belt covers meet FDA / EC regulations.

- Consistent feeding of dies

- Improved productivity

- Reduced maintenance costs

- Long service life

Sausage Belts

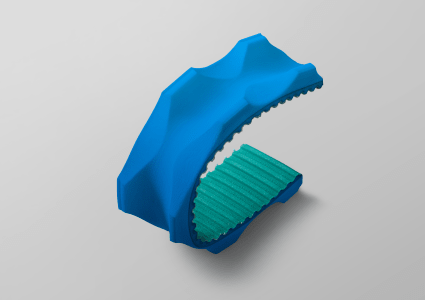

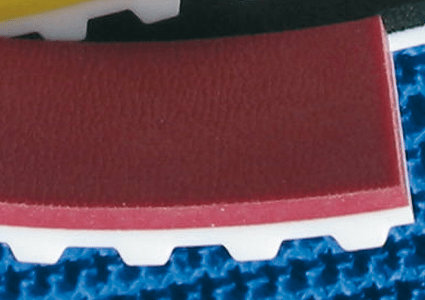

Precision machining and a highly flexible Silam cover on a polyurethane aramide reinforced Timing Belt ensures maximum productivity and belt life, even at reduced ambient temperatures.

Our blue food-approved antimicrobial Sausage Belt Covers meet and exceed the most challenging Food Safety demands and support your HACCP programme. Their sealed edges will protect the belt’s reinforcement and eradicate possible product contamination.

Haul-off and Cable-pulling Belts

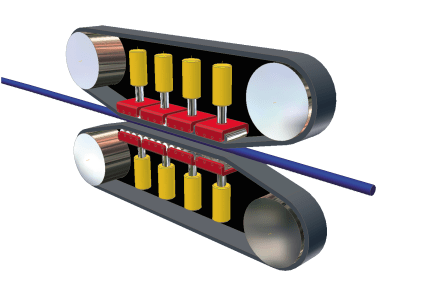

Haul-off and Cable-pulling Belts, designed to operate in pairs on caterpillars, are precision-made to exact specifications.

The combination of hardness, thickness and friction properties of the covers deliver an excellent pulling / clamping force ratio, and their special wear-resistance and low-aging qualities ensure a long service life.

A wide range of covers are available, offering different hardness and friction coefficients.

Belts for the Sanitary Paper Industry

Products such as diapers and sanitary pads are assembled with high precision on moving belts at speeds up to 400 meters per minute.

The high-friction cover on these belts, together with the vacuum that is applied, hold the product in place while it is assembled, cut, folded and packed.

Top-compression and Seam-compression Belts (for the Corrugated Industry)

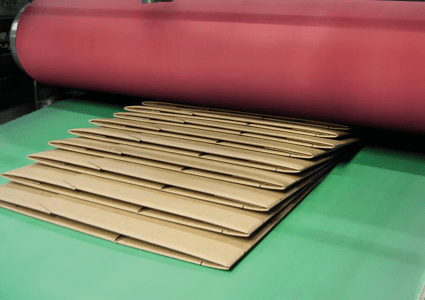

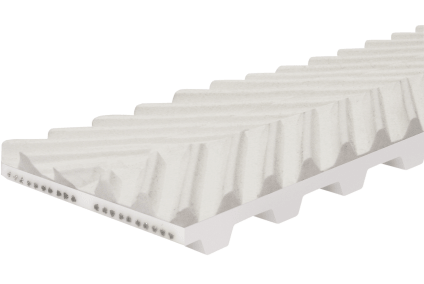

These belts hold folded boxes which have been glued carefully in place during transport and drying.

The weight of the belt holds the boxes down and the soft thick belt cover adapts to the shape of any folded box, large or small.

Specially constructed from non-marking flexible materials to preserve product quality.

Pull-down belts

High performance belts for this demanding application.

Thanks to their friction covers, Pull-down Belts consistently move a plastic film (wrapped around a steel tube) downwards in a controlled start-stop movement.

Our Pull-down Belts are ideal for this work, and they’re all non-marking and machined specifically to fit the task they perform.

- High-performance

- Wear-resistant

- Tear resistant

- Non-marking

Covering Materials

Our range of Covering Materials consists of more than 60 different types divided into 4 segments (Rubber, PU & PVC, Cellular and special Covering Materials) allowing us to customise belts for specific applications.

Outstanding mechanical and chemical properties, together with special fabrication techniques, deliver the high-performance operation and precision customers want.

Rubber

Our rubber covering materials (natural rubber, nitrile rubber and synthetic rubber) are available in multiple colours and offer surfaces with excellent grip, good abrasion resistance or high cut and tear resistance.

PU & PVC

A wide selection of PU and PVC covering materials are available. The materials are available in multiple colours.

Cellular

Natural sponge rubber, neoprene sponge rubber and cellular polyethylene are some of the cellular covering materials Schiki Belting is offering.

Construction varies in degrees from open cellular construction to very high density fully closed construction, with differing advantages and benefits.

Many colours are available.

Special

In some cases, extraordinary requirements are imposed on the covering materials. Therefore, Ammeraal Beltech has a selection of special materials, with specific properties, colours and surfaces to meet customer demands.

For example, technopolymer is a material offering high grip, good oil and fat resistance, excellent abrasion and tear resistance.

Fabrication & Accessories

Semi-finished belts can be customised to exact requirements.

In our fabrication centres, belts are trimmed to size for length and width. Belts can be made endless by means of various splicing methods and can be engineered with holes and grooves.

They can also be fitted with accessories such as carriers, ropes, cleats and sidewalls.

Covering

Covering materials determine a belt’s unique set of properties, such as friction, flexibility; wear resistance and oil and fat resistance.

Schiki Belting can apply an extra cover to almost any base belt, whether it is a standard belt, a high-performance flat belt or a timing belt. We offer an extensive range of covering materials, including rubbers, PVC, polyurethane, cellular materials and other special materials.

Machining

Examples of machining are:

- Grooves for v-guides and for vacuum belts

- Perforated holes created by water jet cutting, punching or drilling

- Grinding (full surface or profiles)

- Embossing of thermoplastic covers

- Milling recessed slots

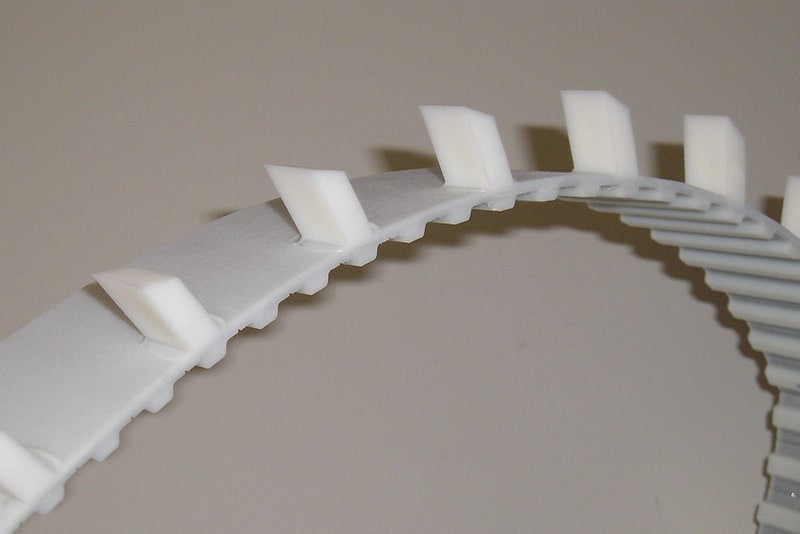

Cleats

Cleats are a popular accessory. Different types are available.

Welding of cleats to belt can be done with infrared welding, friction welding or contact heated tool welding. Cleats are available with metal teeth to enable mechanical attachment to the belt.

In the case of PU belts, welded-on profiles / cleats can be made from the same material as the body of the belt.

Pulleys

Pulleys for timing belt applications can be selected from the standard range or they can be manufactured according to specific drawings and requirements. Standard range consists of pulleys for all common timing belts with standard widths, diameters and construction.

Materials:

- aluminum

- steel

- cast iron

- plastics

V-guides

Fabricated v-guides are available for timing belts: PU Linear and PU Flex Belts.

V-guides can be fit to any belt type in any width and length combination.

The guides can be added onto the back side of the belt.