Logistics

Distribution & Warehousing

Today, accurate and quick order-picking and distribution are key to successful business performance. Maintaining your operations at optimal standards means creating the most reliable and highest-quality system possible, and for that, you need the best partner you can find.

Growing demand of B2C has resulted in the emergence of multiple delivery models and distribution hub types:

- Receiving Centres

- Fulfillment Centres

- Sortation Centres

- Traditional Distribution Centres

Most of these involve a basic model of receiving (infeed), sorting and dispatching (outfeed) which we concentrate on in this section.

Unloading / Loading (Telescopic Boom)

Loading and unloading parcels directly from trailers / vehicles with telescopic conveyors. Telescopic conveyors extend into the vehicle and collapse away after use.

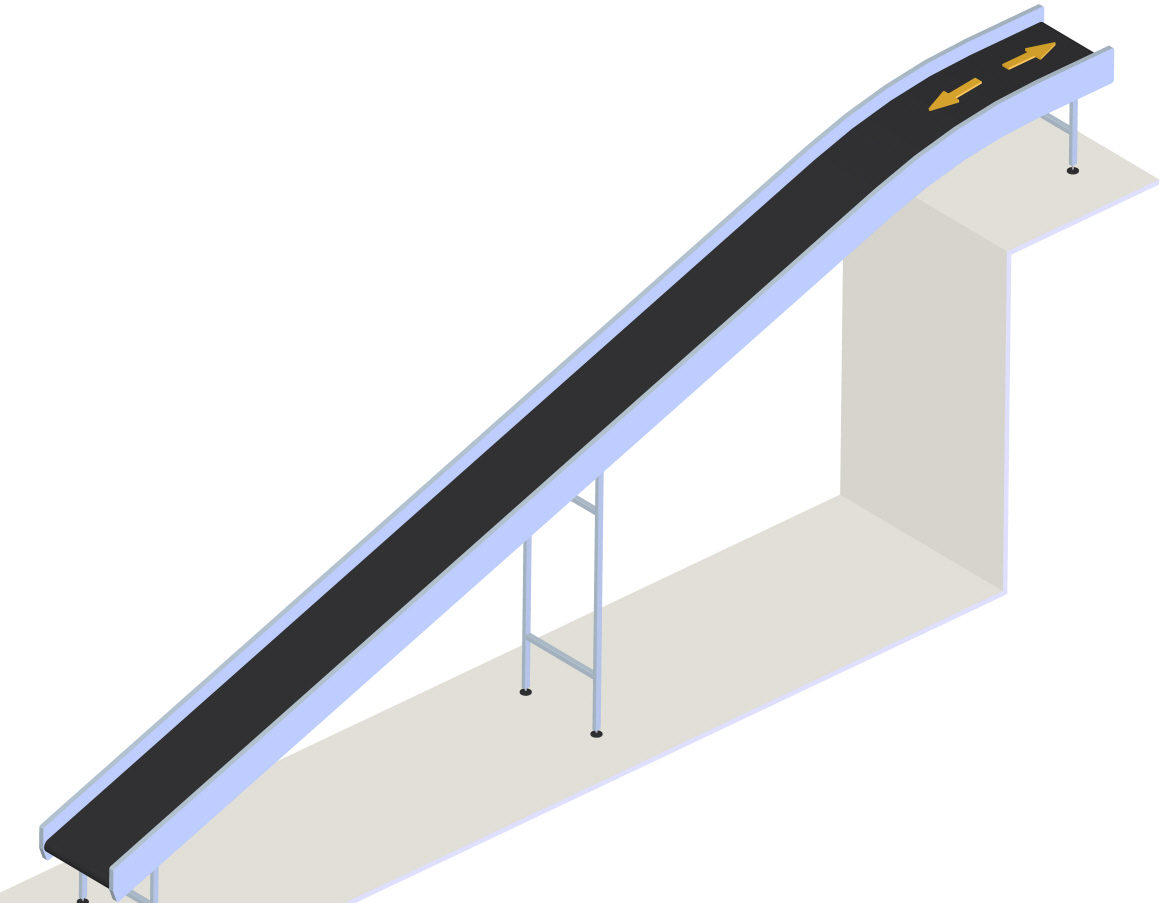

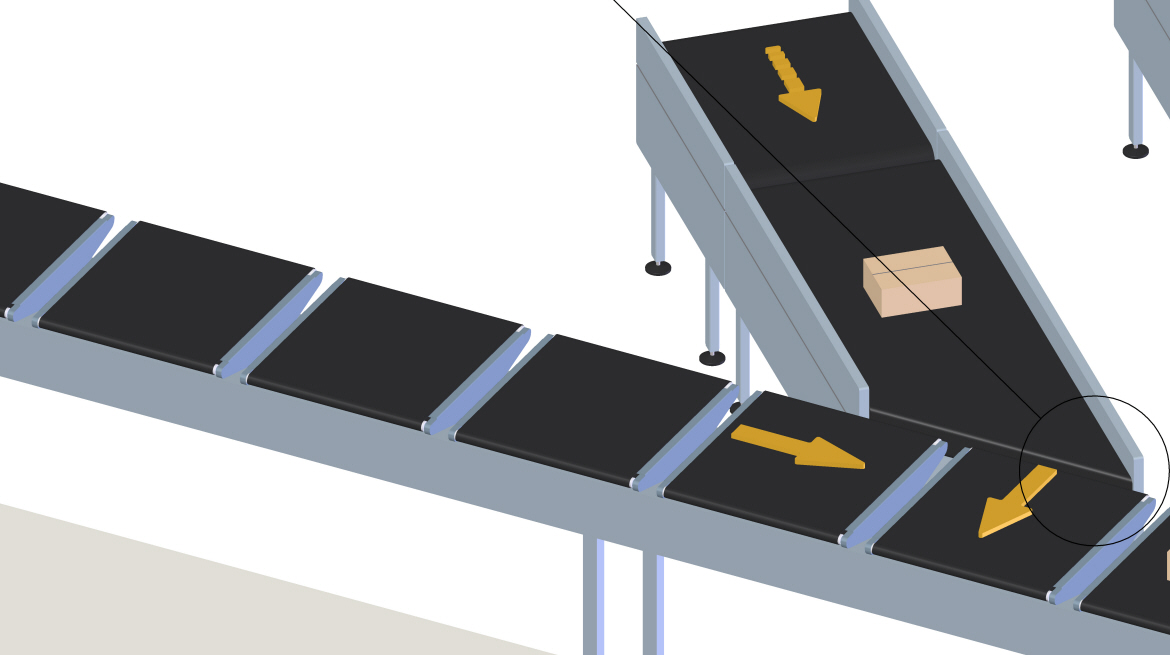

Transportation – Incline / Decline

Parcels often need to change levels within the operation such as inclines from the infeed (trailers / booms) to sorter system levels.

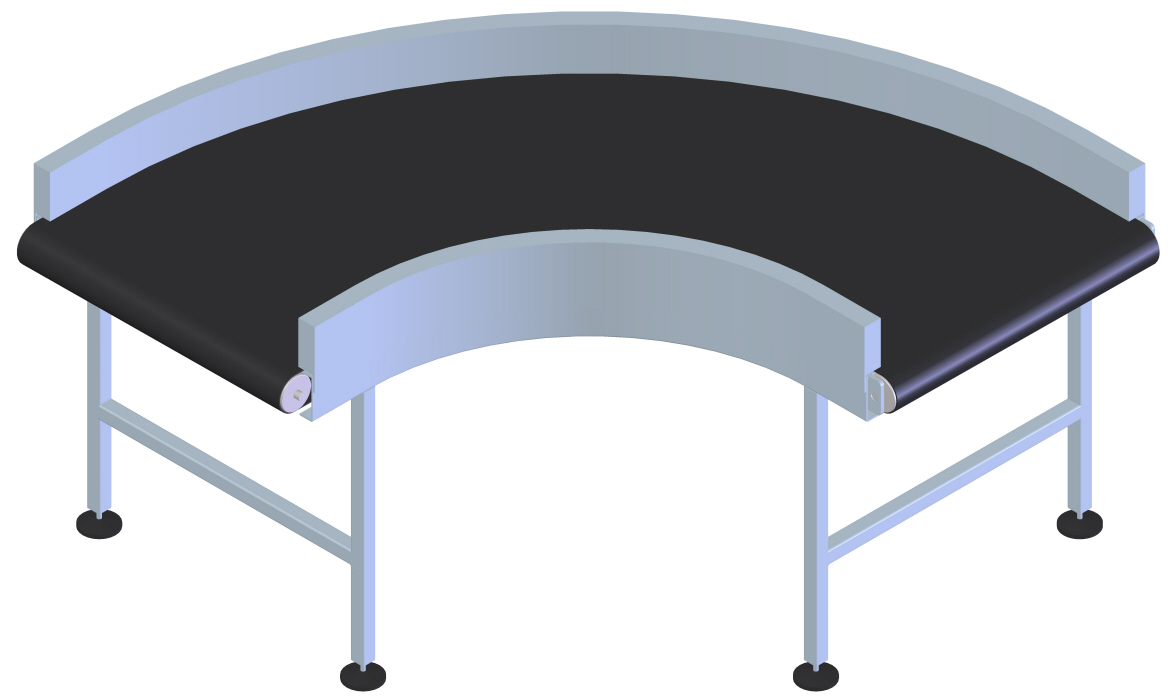

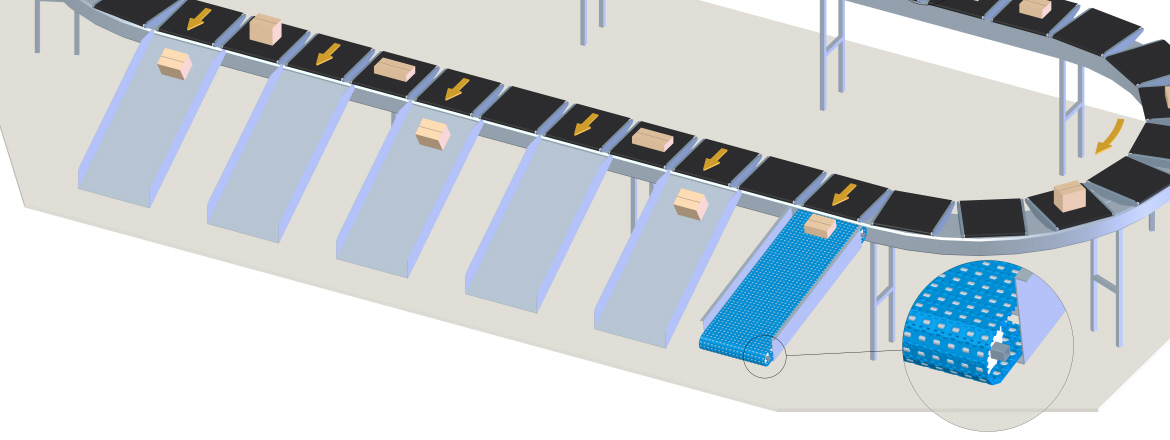

Transportation – Bends / Curves

Power turns, curved conveyors / belts, change the direction of the line flow in the system.

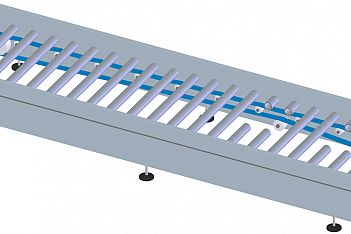

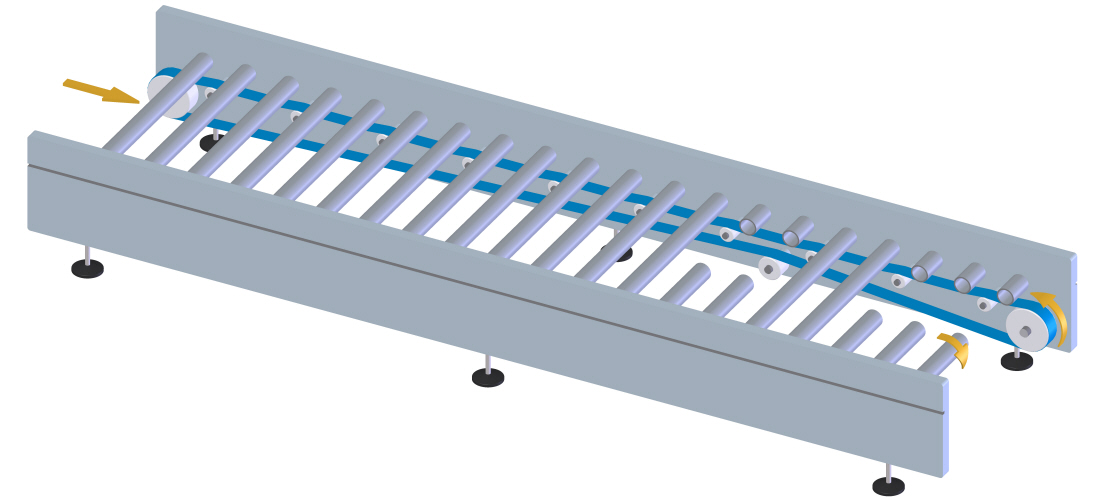

Transportation – Roller Drive Systems

In material handling, live roller conveyors are essential. It is not only for A to B transport, order picking or sorting processes are also done on live roller drives conveyors.

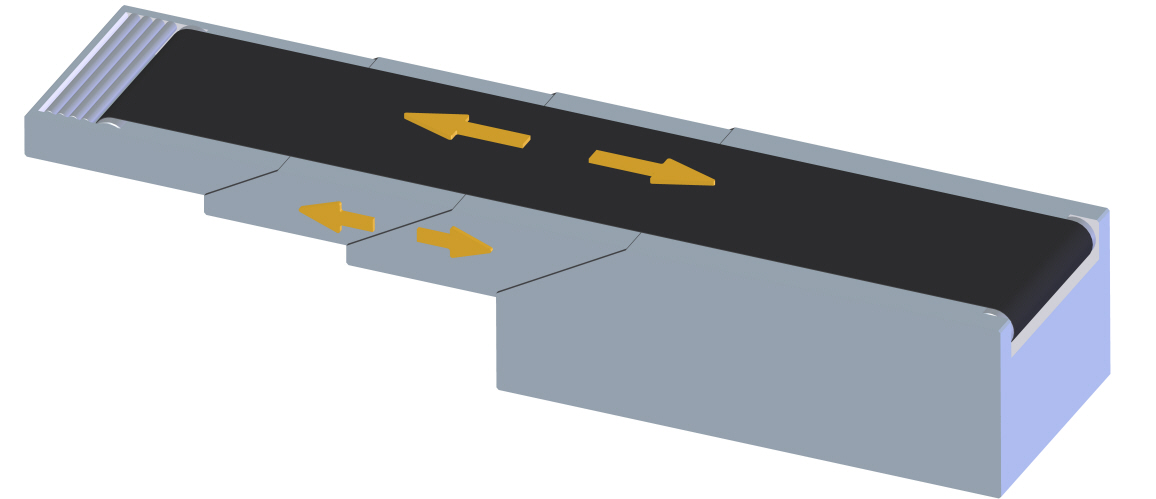

Merge / Takeaway

Merge conveyors are designed to link conveyors within the system, precisely adding parcels from one conveyor line to another at high rates of speed.

Sorting (Cross Belt)

Cross Belt Sorters are completely at home in the high-speed environment helping to minimize transfer times while maximizing conveying performance.

Postal Automation

Schiki belting is geared to meet the exact demands of the Mail Sorting Industry. Every day, billions of letters are sorted and distributed for further transport to all parts of the world.

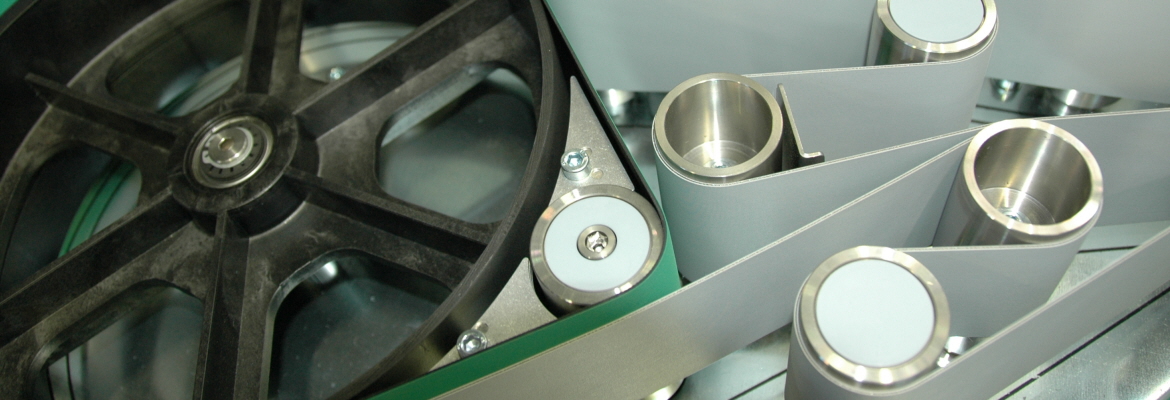

Culler Facer Canceller

The first sorting machine in the sorting process usually is the CFC (Culler Facer Canceller). It receives bulk mail, sorts out unsuitable mails, checks correct postage and detects orientation of mail pieces and turns them into a defined orientation.

Letter Sorting

With a process speed around 4 meter per seconds all standard letters will be sorted automatically and will generate an output of more than 60,000 pieces per hour. For each section in the sorting process Ammeraal Beltech offers the right solution.

Flat Sorting

Flat sorters are sorters for larger format mail pieces. They handle paper, cardboard, plastic wraps and open catalogues with a capacity of up to 43,000 pieces per hour.

Open Mail Handling System

The system enables a wide range of mail to be processed, from standard letters to flats of all types and packaging. The Open Mail Handling System has an integrated tray handling system, which transport the full and empty trays within the operating area of the machine.

PDF Catalog

PDF Catalog