Fabrication & Accessories

Plain belt material is fabricated to customise the belt to your specifications, for example, cutting to the right length and width.

An important fabrication job is making the belt endless. Belts can be made endless by means of various splicing methods.

Synthetic Belts can also be fitted with accessories such as cleats (also called carriers), ropes and corrugated sidewalls.

Splicing

All open length belts will need to be secured at either end to complete the loop. Belts can be made endless by means of various splicing methods.

The splice is generally considered to be the weakest point along the belt’s length and is most susceptible to damage.

Belts are generally made endless with one of the following splice types:

- Finger splice

- Finger-overlap-finger splice

- Stepped splice

- Skived splice

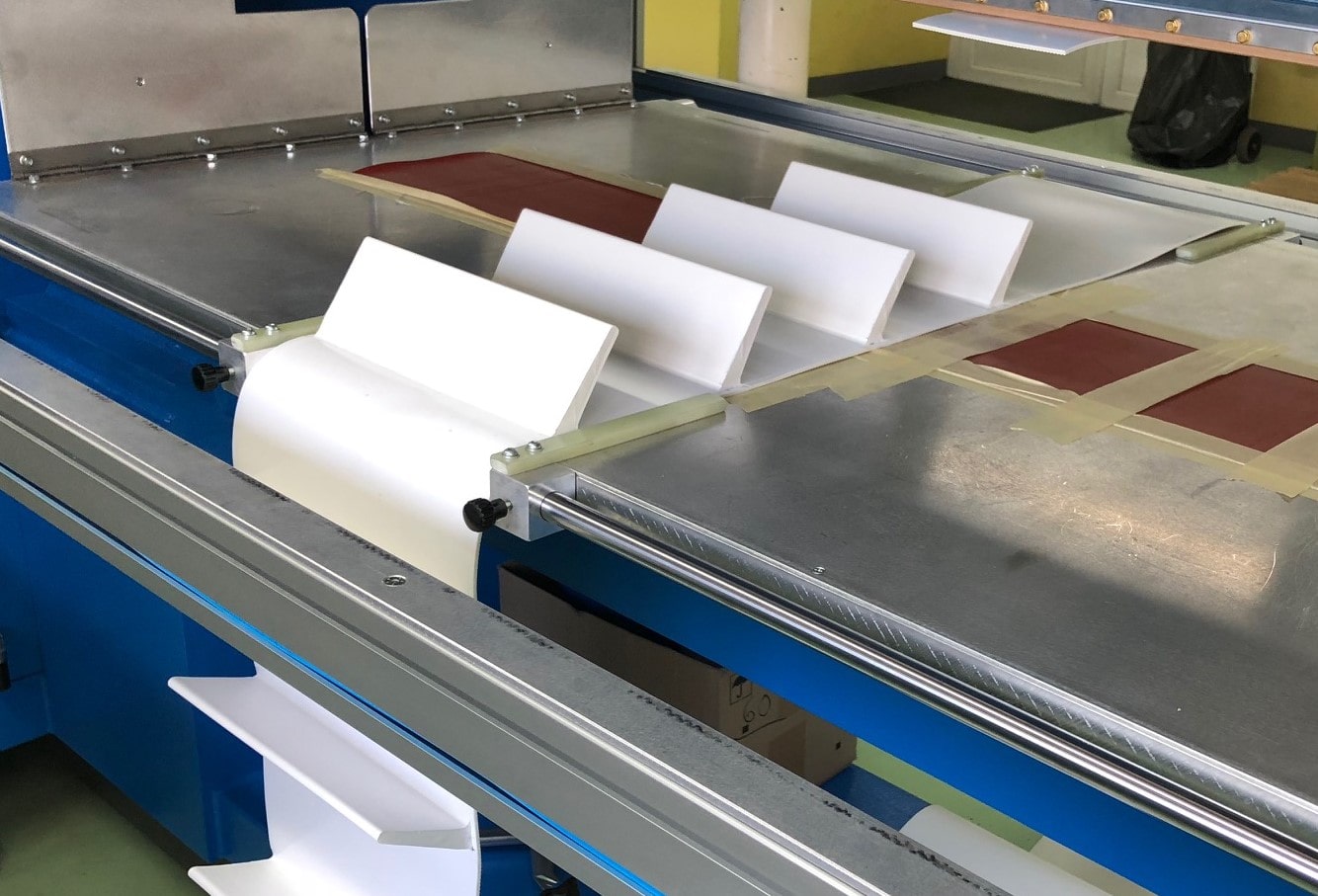

Profiles

We can offer a comprehensive range of profiled belts, capable of meeting all the requirements of industry with respect to efficient product handling. Practically every belt can be embossed with one of over 80 standard available profiles, while specific requirements can be met with custom engineered solutions.

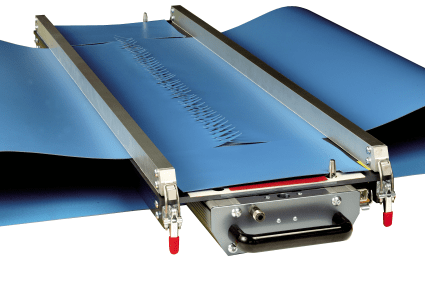

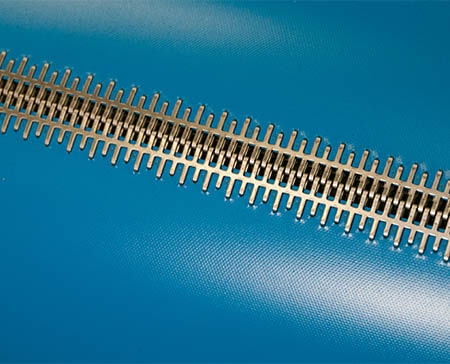

Metal Mechanical Fasteners

Fast belt exchange possible. Main benefit is the substantial decrease of system downtime. Mechanical fasteners are ideal for applications where belt replacement time is an issue

Choosing the proper mechanical belt fastening system is one of the most important steps in splicing a belt. Mechanical Fasteners combine strength and durability with fast, easy installation for a quality, long-term splicing option.

Accessories

Accessories for different purposes are available:

- Cleats (also called carriers) on the topside of the belt for inclined or declined conveying

- Corrugated sidewalls on the belt sides (top) to prevent spillage on the sides

- Ropes used as cleat or sidewall

- Ropes or guide strips on the bottom side of the belt for tracking

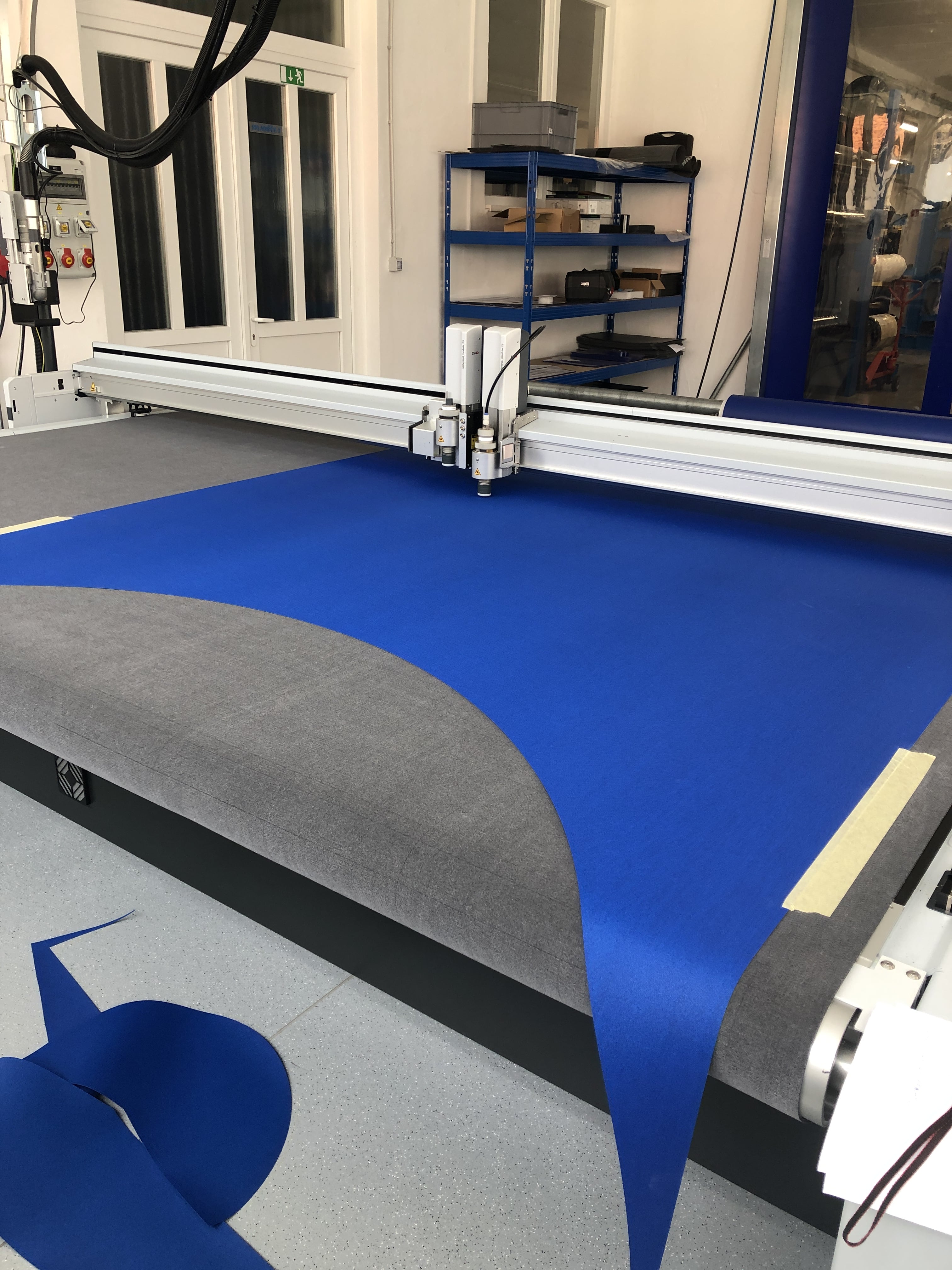

CNC cutting

In our modern production facility Schiki Belting can offer you finished cuts according on customers demands. With our modern CNC cutting machine we can cut all our materials from thicknesses 0.5 – 30 mm in width up to 3200 mm. The materials are cut from the rolls so that lengths are not limited.

In our CNC center we can offer cuts, assorted with different types of conveyor belt materials and all other materials, are designed to meet customer specifications.

Just provide us with a CAD drawing in DXF or DWG formats or send us your wishes in PFD our hand drawings and we will make your product.

We also provide our customers with special belts made by our standard production and upgrade with CNC trim, cut or milling.

Even extremes of strength, exact dimensional tolerances and surface quality specification can be catered for using our modern fabrication techniques.