PTFE Belts

Schiki Belting PTFE belts are the smart solution for a wide variety of baking and freezing applications.

Applications:

- High-temperature or open-flame ovens (e.g. pita & piadina bread)

- Non-stick applications

- Press-baking processes (e.g. tortillas, pizza bases, flatbreads)

- Cryogenic freezing chambers

Product Range

A PTFE or Silicone Coated Belt will deliver premium performance at extreme temperatures for a wide range of Food Industry applications.

Key benefits:

- Excellent release properties, even for sticky foods, such as flour-based doughs, and for sugar-coated or sugar-based products, e.g., doughnuts or chocolate

- Very low friction – high abrasion resistance

- Working temperatures:

- Heat resistant up to +260 °C

- Cold resistant down to -70 °C

- Chemically inert

- Easy cleaning due to non-stick PTFE coating

- EC 1935/2004 and FDA Food Grade compliant

Baking

PTFE belts are the smart solution for a wide variety of baking processes. Flour-based products can be conveyed safely and efficiently through ovens at temperatures up to +260 °C.

Excellent release properties mean that baked goods are transferred easily and undamaged, reducing mess and waste and boosting hygiene.

Cryogenic freezing

Our PTFE belts are ideal for use in cryogenic freezing, a food processing technology that is rapidly gaining popularity next to mechanical food freezing.

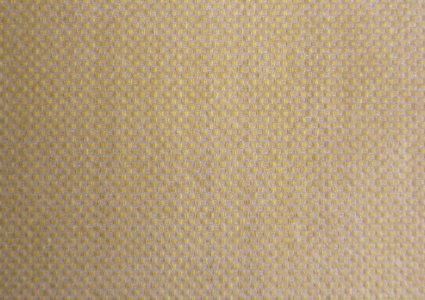

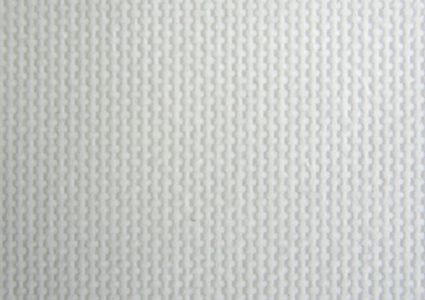

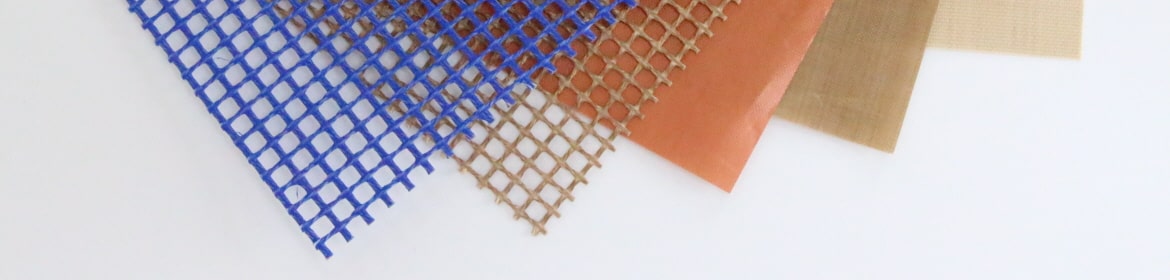

PTFE Coated

Excellent release properties and easy cleaning.

- Standard Fibreglass PTFE 100

- Premium Fibreglass PTFE 100

- DXL Fibreglass PTFE 100

- K50-600 PTFE Kevlar

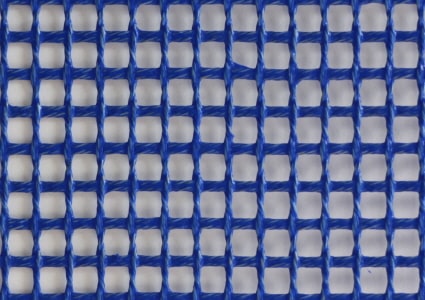

Coated Mesh

Optimal airflow due to open mesh design.

- Double Weft 4×4 Blue PTFE Mesh

- Glass 4×4 Brown PTFE Mesh

- Mesh 1×1 PTFE Kevlar