Tobacco

Green Leaf Processing

Year after year, FDA EU and Pyrolysis regulations become stricter. To help the industry conform, Schiki Belting supplies high-quality halogen-free and nitrogen-free non-toxic belts offering outstanding production performance for greater process reliability and increased throughput.

Our wide range of tobacco belting solutions will significantly improve your overall process performance.

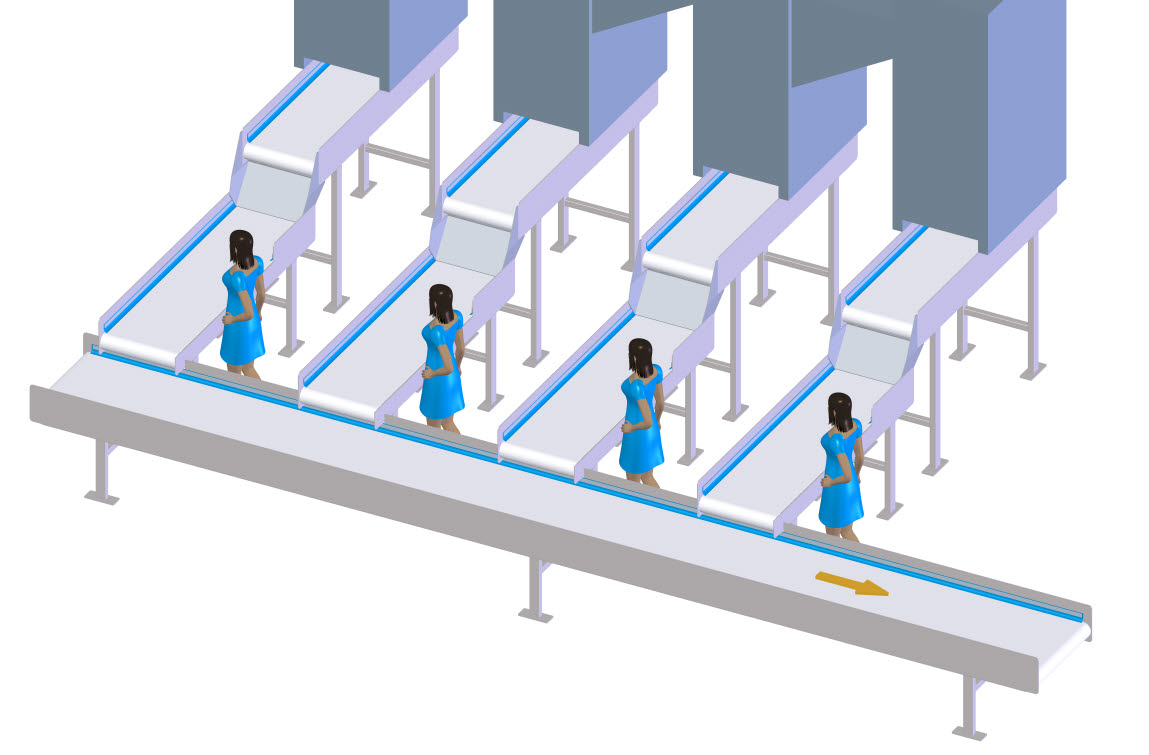

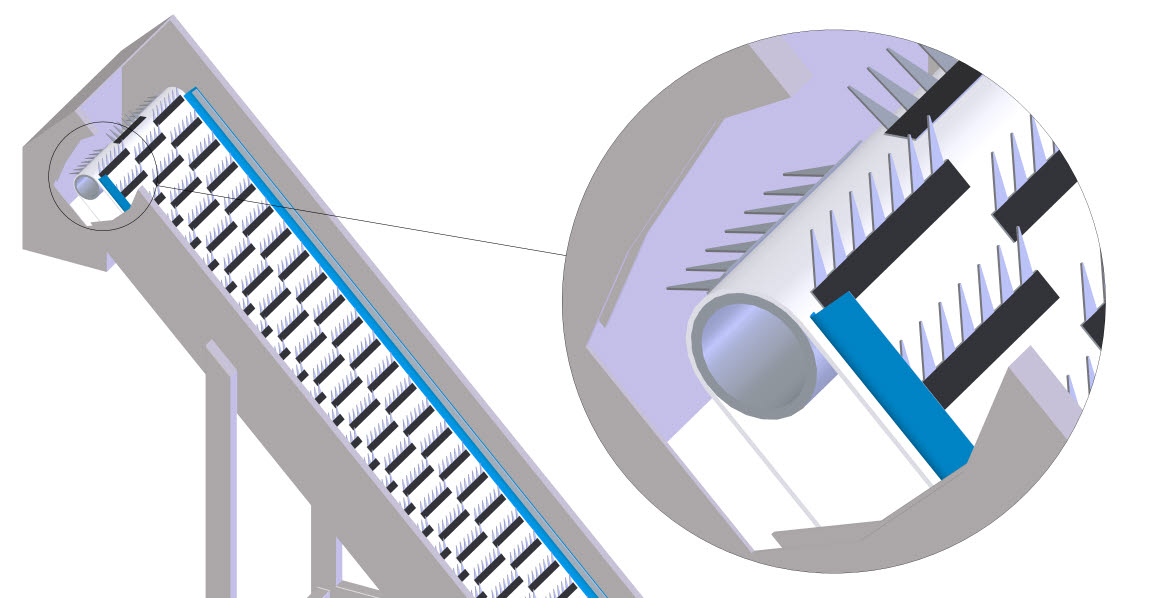

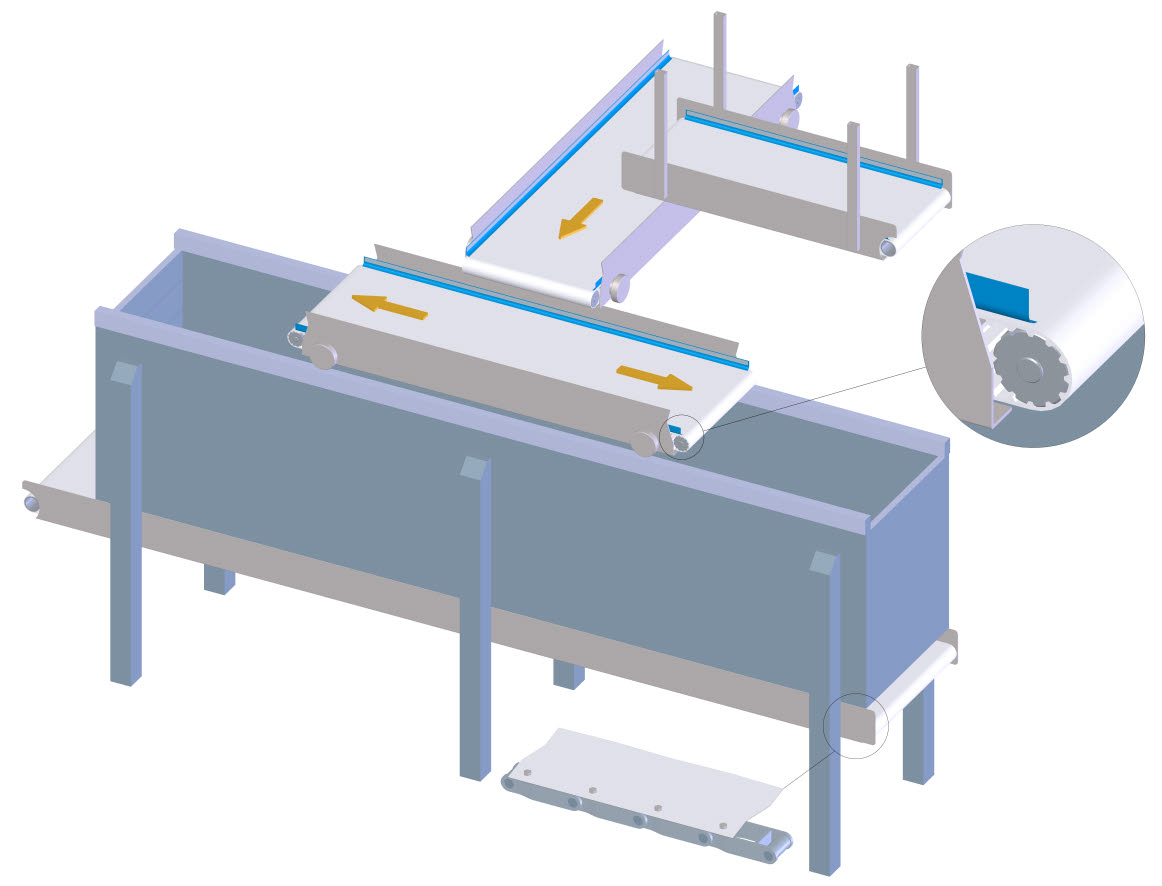

Sorting and Picking

Dried leaves are brought in from the fields. The leaves are picked and sorted, all by hand. Conditions in the processing plants, which run round-the-clock, are difficult; the operating environment is very dusty.

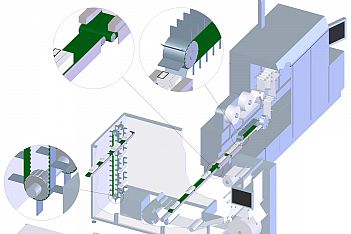

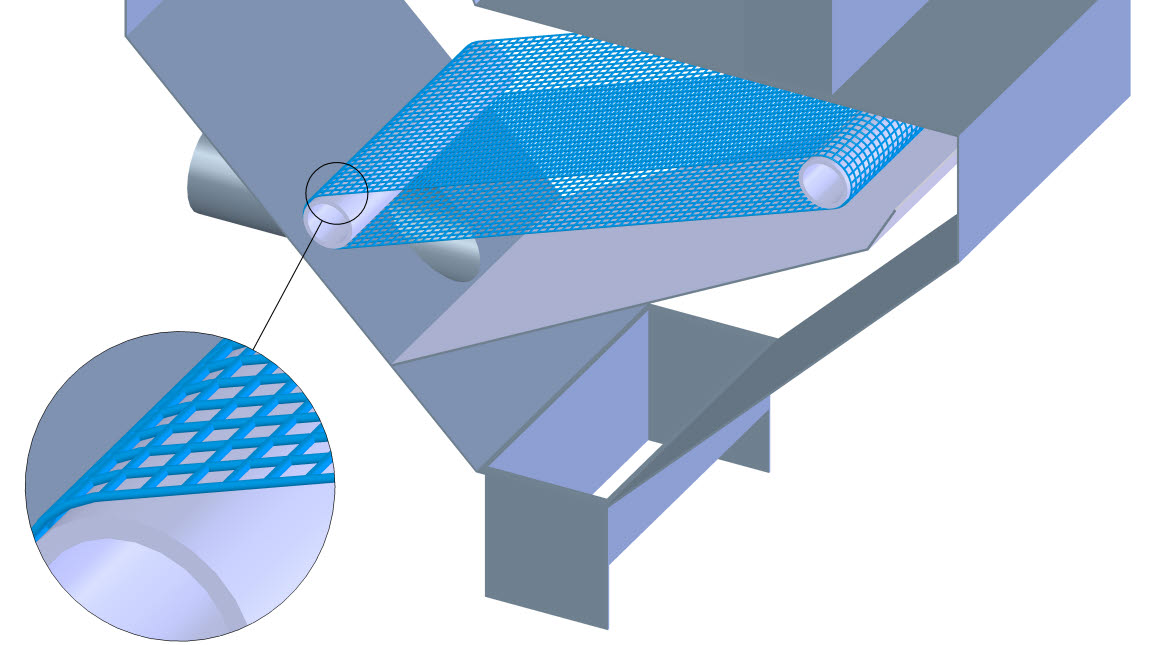

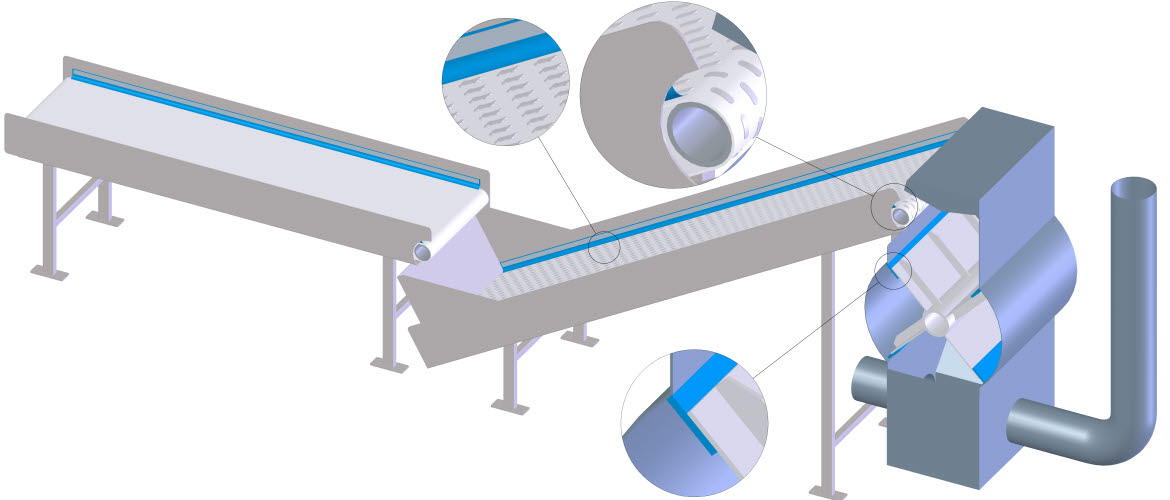

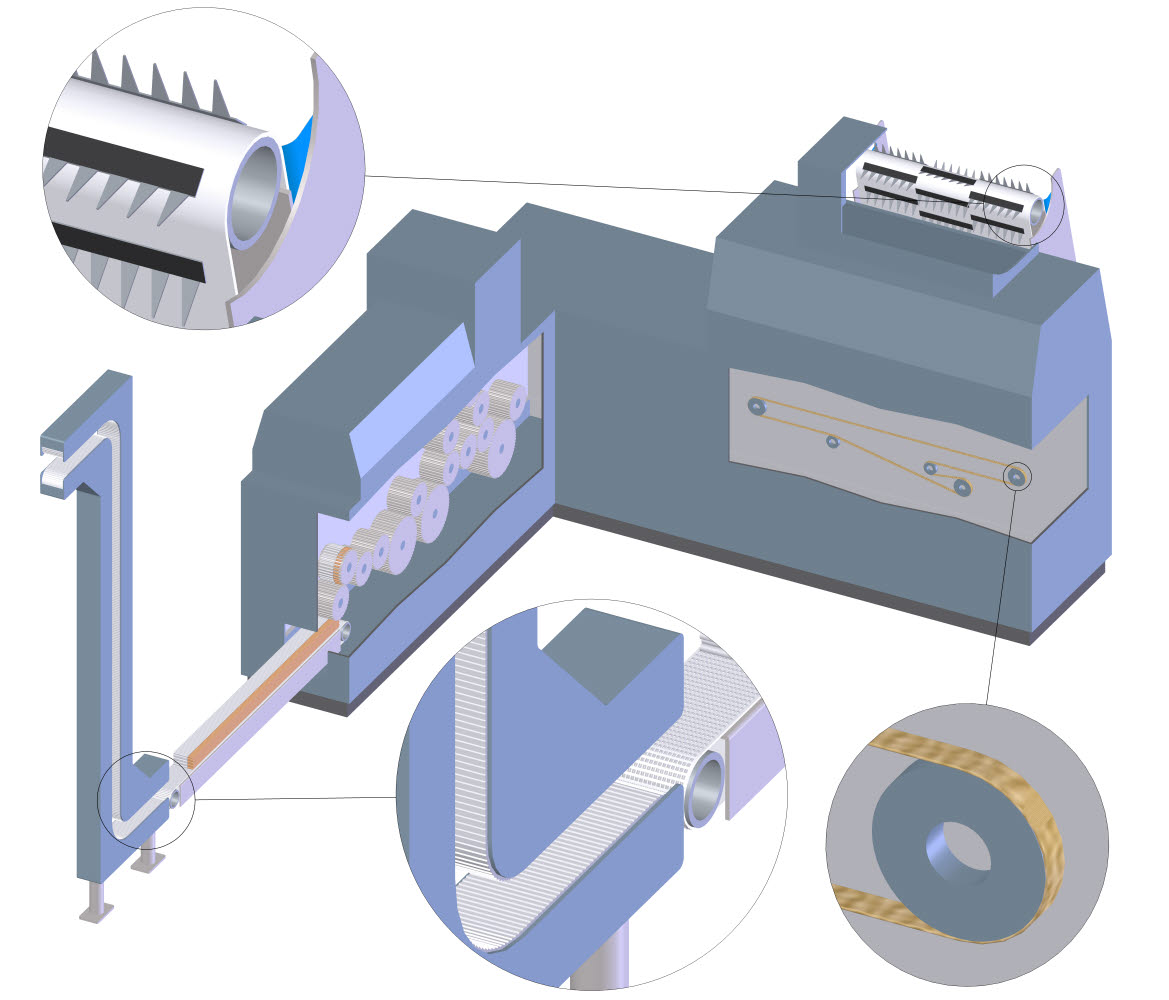

Threshing

In this step, the lamina is separated from the stem and dust and small foreign particles are filtered out.

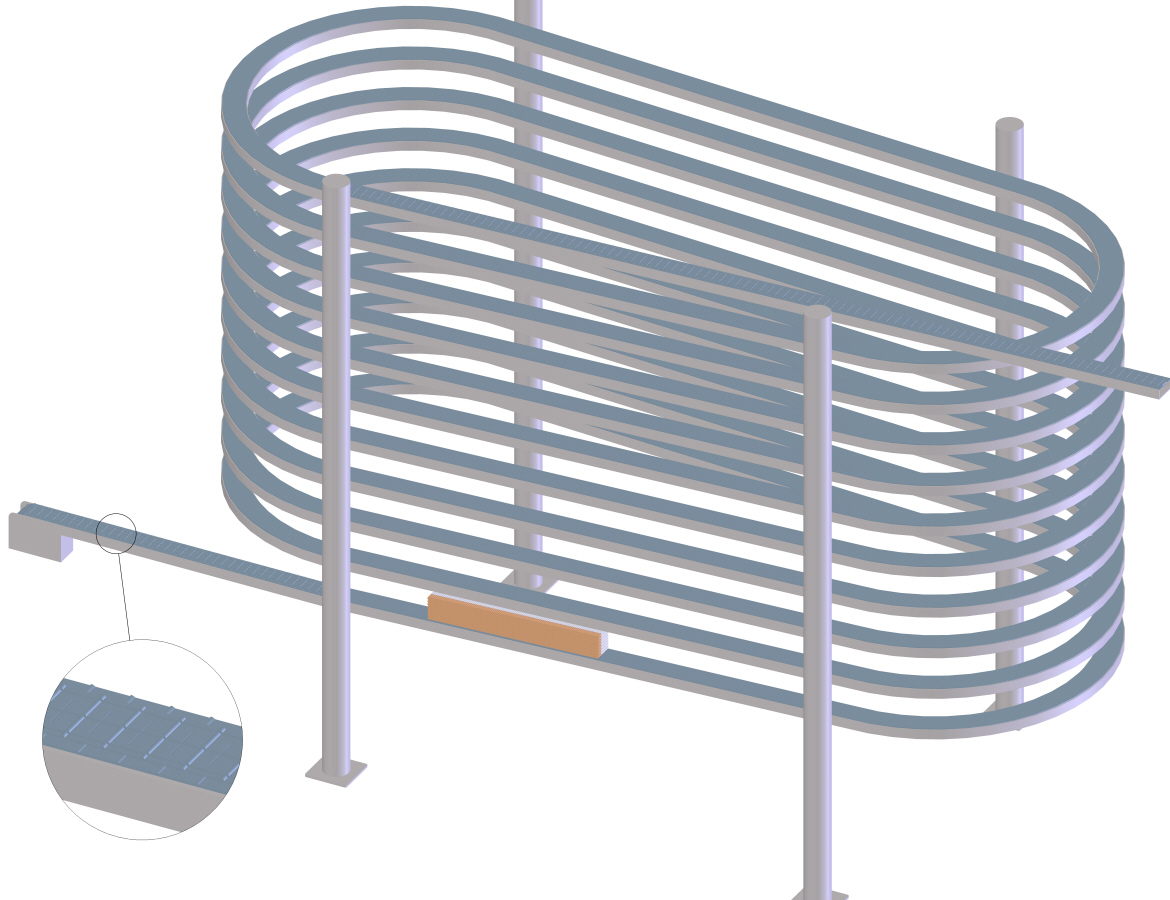

Tumbling

In this step, seals need to be airtight and belt material needs to be tobacco-proof, compressible and wear-resistant. The lightweight rubber fabric range with its natural rubber inner layer has all of these characteristics. The tumblers are fed by incline conveyors.

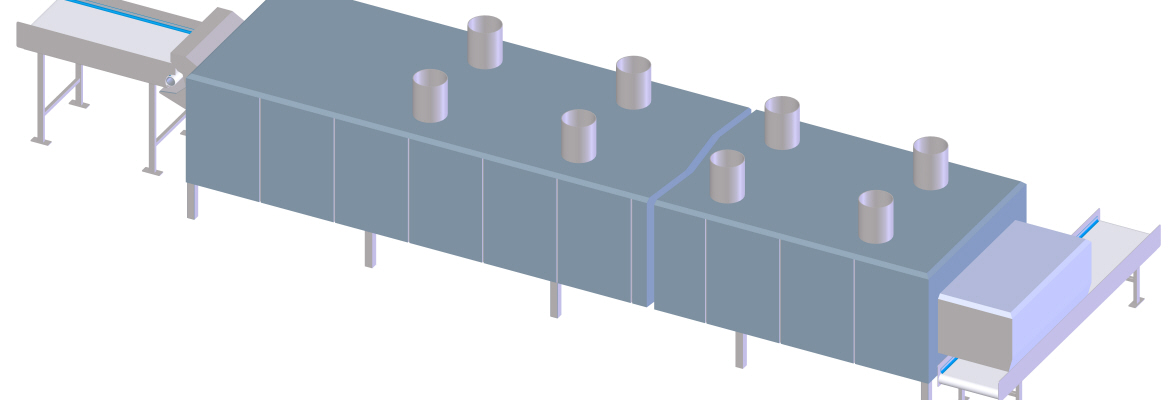

Drying

After threshing and tumbling, all the moisture must be removed from the leaves to make them suitable for transport.

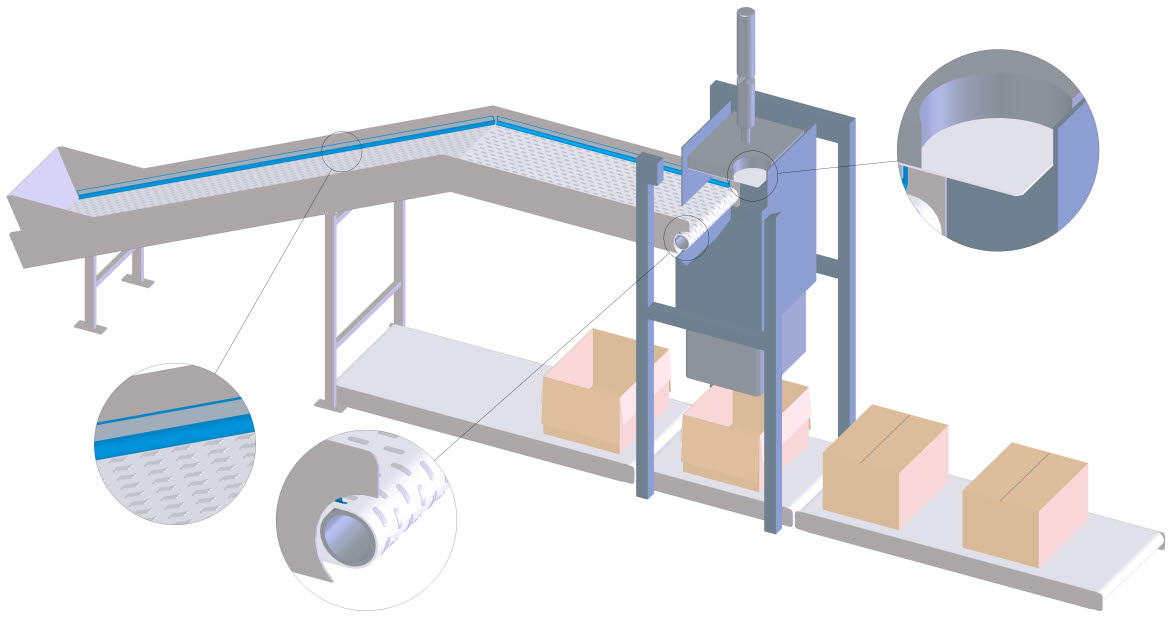

Packaging

Dry leaves and stems are packed separately in carton boxes to be shipped around the world. Hydraulic steel pushers are used to optimise box-filling.

Primary Processing

Primary processing belts need to be hard-wearing and highly resistant to casing and flavouring liquids. They should also be low noise, easy to clean and deliver a long service life.

At Schiki Belting, we have belts with all these characteristics and more; belts with high friction and low friction coefficients, with profiled surfaces, with operating angles of up to 40°, able to trough and with the high lateral flexibility to prevent tobacco dust from spilling.

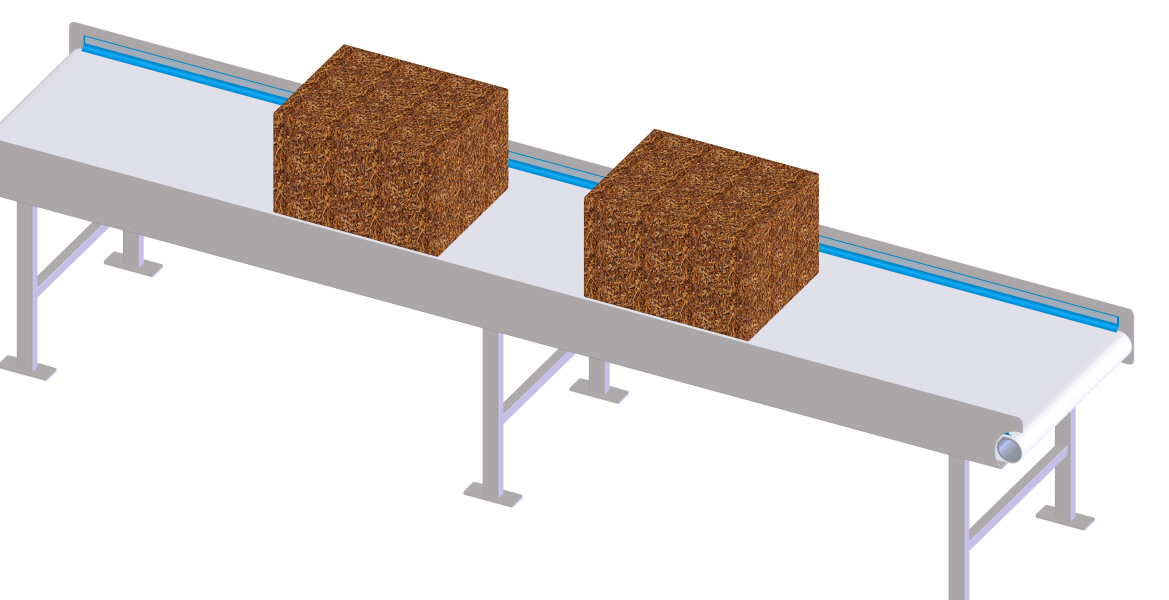

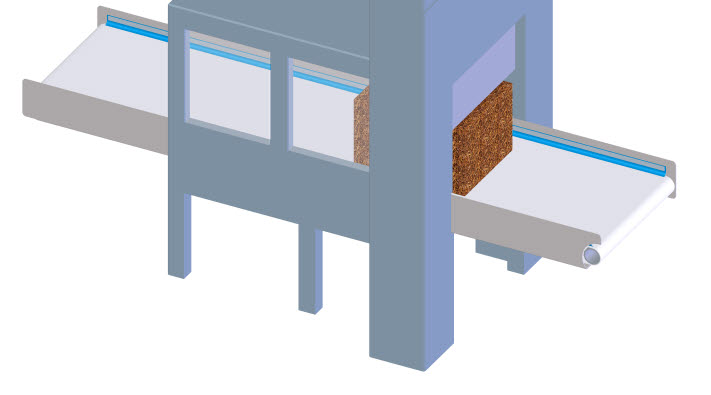

Bale Opening

For this process, belts need to be impact-resistant and have the right friction coefficients to keep the dry tobacco blocks in place on the belt surface.

Slicing

Big tobacco blocks are cut into slices by an automated guillotine system. This operation may take place on a belt or it may occur between two belts.

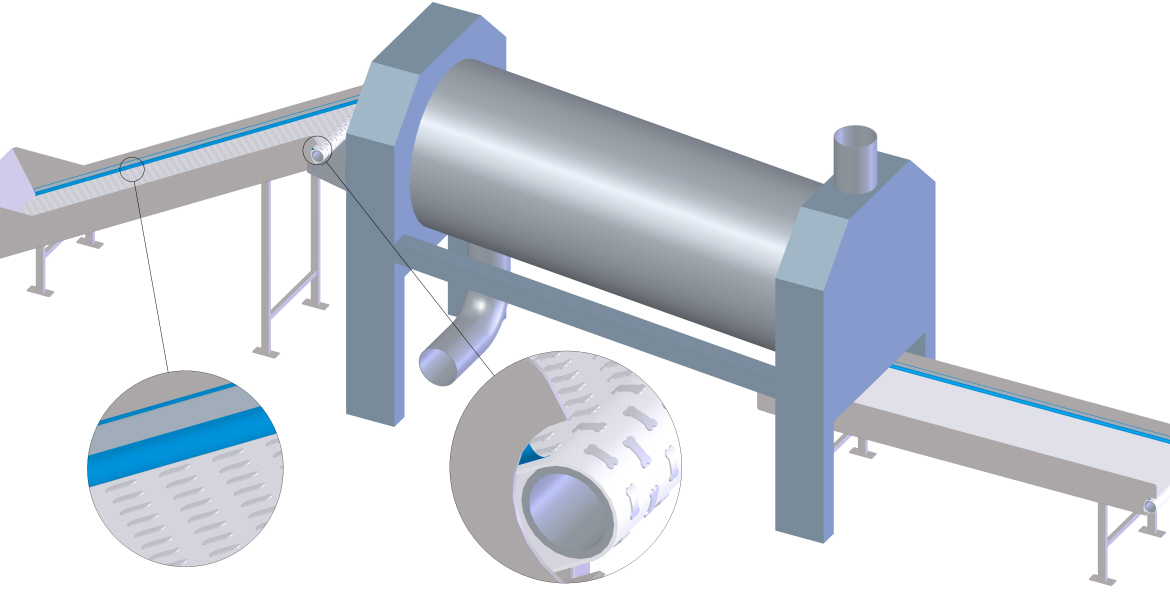

Conditioning and Flavouring

In this step, the slices are taken on incline conveyors to the first DCC (Drum Condition Cylinder). Here the brittle leaves are treated with heat and steam to make them flexible again. Additional fluids (to add flavours) may also be present.

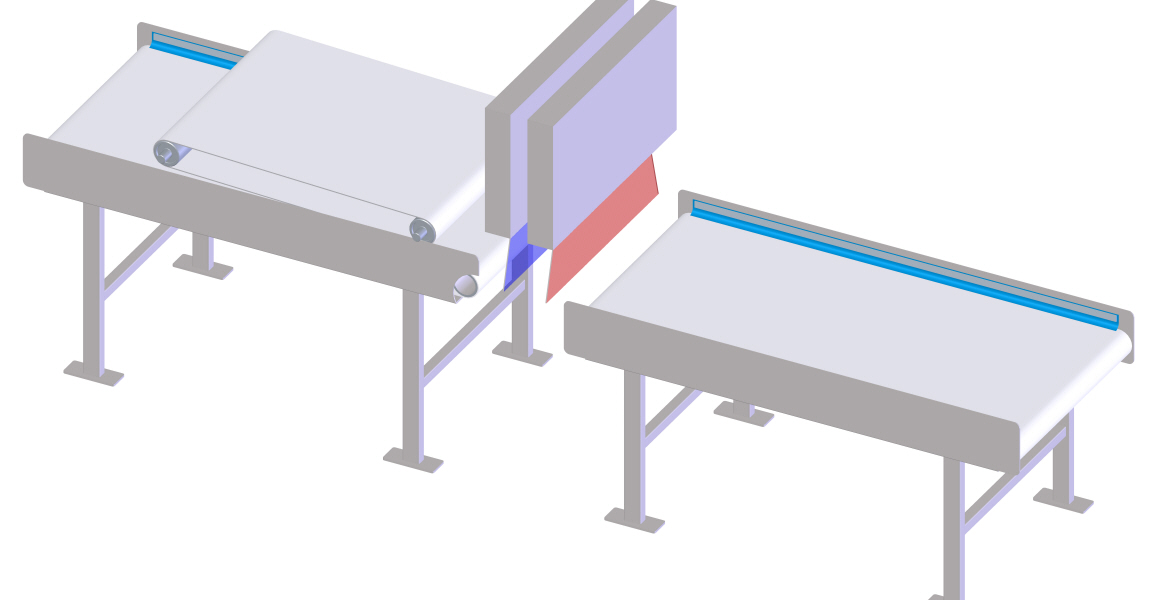

Scanning and Sorting

During Green Leaf Processing, NTM (Non-Tobacco Material) has already been manually removed. In Primary Processing, companies are using high-tech scanner equipment for the smallest bits. Detection is based on differences in material structure and colour.

Blending

The mixing of different types of tobacco according to precise recipes to produce a characteristic, homogeneous blend.

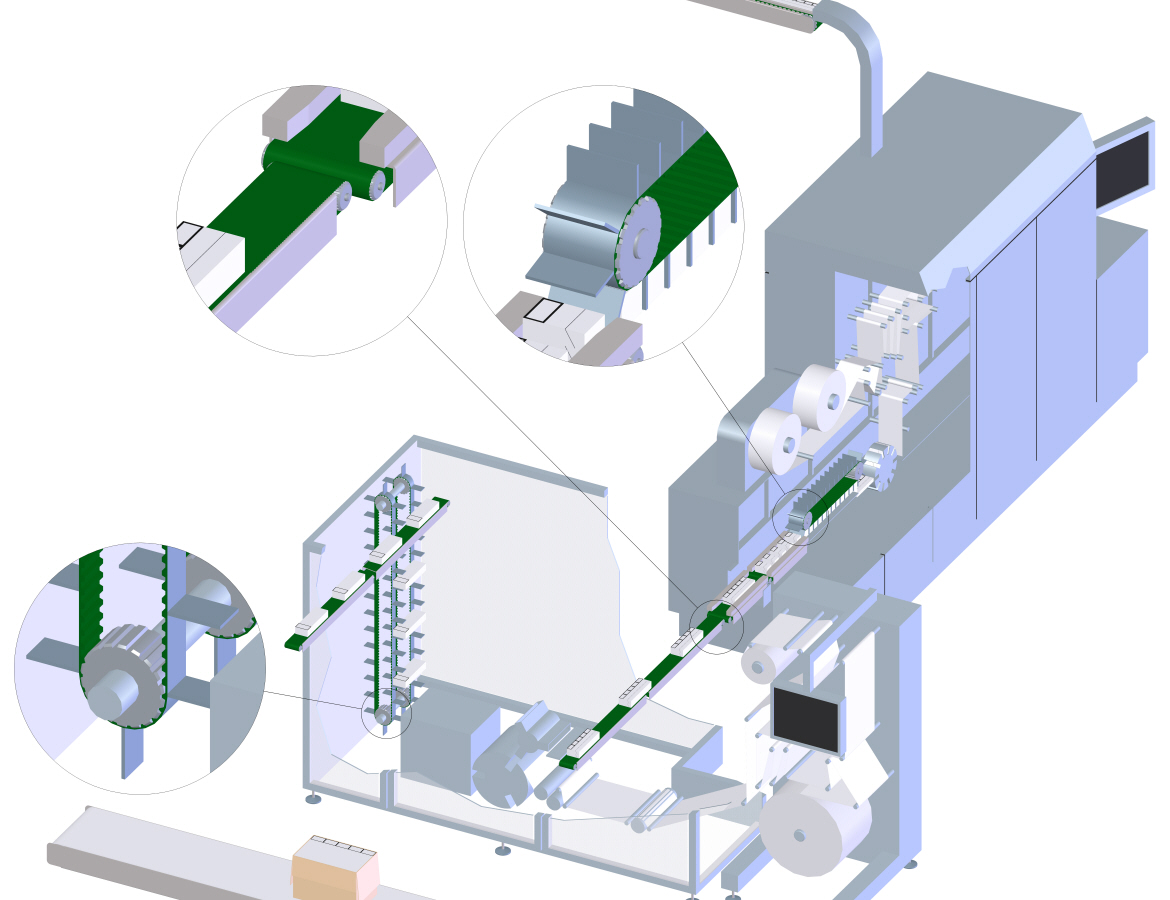

Secondary Processing

Secondary Manufacturing Processes for cigarette production require special belting properties. All applications with direct tobacco contact must have non-toxic solutions, while the transfer of cigarettes into packaging machines and of cigarette packets from bundlers / cartoners into case packers and palletizers require belts with low or high-grip properties.

Our product range covers all these applications.

Cigarette Making

The cut tobacco is transported to the cigarette maker by air (tubes) and then circulated in the feeder unit. Once at the maker, the suction tape collects and conveys the tobacco to create a tobacco rod. The finished cigarettes are transported on belts out of the maker.

Transfer and Storage

The belts that link the cigarette maker and the buffer can run both horizontally and vertically. Either way, the profile must not damage the cigarettes.

Packaging

The enclosing of products with wrapping materials in order to protect, collect and conserve tobacco goods and present a convenient and attractive product.

Logistics

Boxes filled with multiple packages of cigarettes are often transported to a central palletising area. During the transport, it passes different sorting steps to end at the correct place.

Tobacco_flyer

Tobacco_flyer