Timing Belts

The Timing Belt range offered by Schiki Belting is the ideal solution if your product or production process demands accurate synchronisation of time and distance.

Our offer includes the widest range of high performance profiles, allowing to select the best technical solution in every drive application.

PU Linear

Open length thermoplastic PU Timing Belts are available in open end rolls or endless jointed.

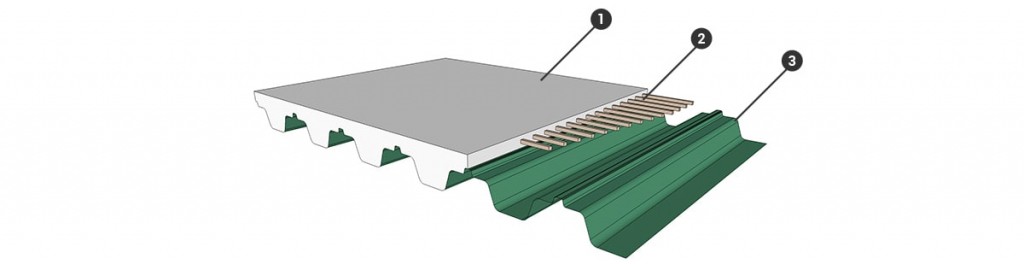

Belt structure:

1) Body made of thermoplastic polyurethane 92 ° Sh.A with high wear resistance.

2) Tension cords made of steel with high tensile strength and high elastic modulus.

3) Fabric on teeth PAZ, PAR on the back or PAZ-PAR (on back and toothing), on request, used in order to: reduce the coefficient of friction, improve the tooth engagement, reduce the noise.

- Excellent length stability

- The minimum tension decay

- Low pretension and shaft load

- Pretensioning minimized

- High abrasion resistance

- Silent operations

- Maintenance free

- Resistant to aging, ozone and hydrolysis

- Working temperatures between -25°C to + 80°C

- High resistance to oils, fats, grease and hydrocarbons

- Good resistance to acids and alkalis

- Executions available on request: Silicon free, FDA, antistatic

- High linear and angular positioning precision

- automatic doors

- elevators

- automated handling devices

- linear guides

- logistics

- positioning systems

- shipping lines

- wood industry

- textile industry

- screen printing industry

- glass industry

- marble and stone industry

- packaging industry

- robotic systems

- tobacco industry

- paper industry

- chemical and pharmaceutical industry

- T2,5; T5; T10; T20

- AT3; AT5; AT10; AT20

- SAT10

- TK5-K6; TK10-K6; TK10-K13(SELF CENTERING)

- ATK5-K6; ATK10-K6; ATK10-K13(SELF CENTERING)

- MXL; XL; L; H; XH

- HTD(3M; 5M; 8M; 14M)

- RTD(5M; 8M; 14M)

- STD(S5M; S8M; S14M

- GTR(14M)

- EAGLE(5M; 8M; 10M; 14M)

- POLY-V K

- T10– AT10 – HTD8 – Total Protection

- TT5

Special cords:

In order to optimize the application needs, our belts can be delivered with special cords:

- HFE high flexibilty: they allow the use of pulleys and idlers with reduced diameter up to 30% compared to standard.

- HPL high resistance:the cord cross section is increased (when compared to the standard belt) and this results in a lower belt elongation and more precise positioning accuracy.

- HPFE high resistance and flexibility: this kind of cord combines high rigidity and a better flexibility.

- Stainless Steel: suitable for applications in aggressive environments or for food applications.

- Aramid fiber: non-magnetic, excellent flexibility and low weight of the belt.

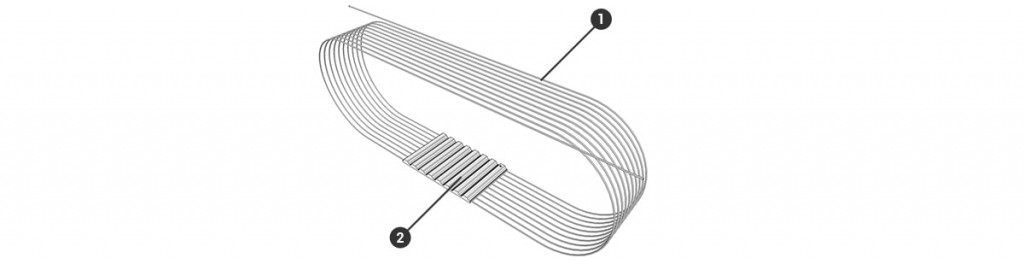

PU Flex – Truly endless

The Flex belts are manufactured with high tension strength steel tension cords and with high wear, abrasion and tear resistant polyurethane.

Having no splice or welding, the belts have no weak cross sections. Flex timing belts are therefore ideal for high speed power transmission and high load conveying applications. Available in a wide range of profiles and pitches, produced in any required length, tooth by tooth from 800 mm to 24,000 mm in order to provide the best flexibility in application.

Available also as dual-toothed timing belts (DUAL)

Belt structure

1) Body thermoplastic polyurethane 92 ° Sh.A high wear resistance.

2) The traction element consists of steel cables high strength and high elastic modulus.

- Excellent length stability

- Minimum tension decay

- High abrasion resistance

- High precision linear and angular positioning

- Silent operations

- Maintenance free; Resistant to aging, ozone and hydrolysis

- Working temperatures between -25°C to + 80°C

- High resistance to oils, fats, grease and hydrocarbons

- Good resistance to acids and alkalis

- Matching with other thermoplastic materials

- Executions available on request: Silicon free, FDA, antistatic

- Squaring machines for ceramics

- Squaring machines for glass

- Packaging machinery

- Logistics

- Textile machinery

- Positioning systems

- Tobacco machinery

- Mail sorting machines

- Robotics

- Wood working machinery

- T5; T10; T20

- AT5; AT10; AT20

- MXL; XL; L; H; XH

- HTD(5M; 8M; 14M)

- RTD(5M; 8M; 14M)

- STD(5M; 8M; 14M)

- EAGLE(8M; 10M; 14M)

- ATK10-K6;

- ATM10

Special cords:

To optimize the use of ELA-flexSD ® in each application, they are also available designs with special cords:

- HFE high flexibility allow the use of pulleys and tensioners diameter of up to 30% lower than the standard.

- HPL resistance HPL: with the strand section increased, allows lower elongation and consequent better positioning accuracy.

- HPFE high strength and flexibility combine high stiffness and improved flexibility.

- Stainless steel: for highly corrosive environments or in food applications

- Aramid fiber: non-magnetic, excellent flexibility and low weight.

Fabrication & Accessories

Semi-finished belts can be customised to exact requirements.

In our fabrication centres, belts are trimmed to size for length and width. Belts can be made endless by means of various splicing methods and can be processed with holes and grooves.

They can also be fitted with accessories such as carriers, ropes, cleats and sidewalls.