Use Indication

There are more usages for Synthetic Belts besides the normal A-to-B (horizontal) conveying of goods, where a specific belt is needed to get the job done.

Some examples:

- Curved conveying

- Troughed conveyors

- Inclined or declined conveying

Troughed (roller support)

The main use of troughed roller support is in conveying bulk materials such as sand, grain, etc.

Support in such cases is provided by trough idler assemblies, which can be fitted as add-on items to a basic conveyor frame.

Belts used in troughed conveyors need to have good lateral flexibility.

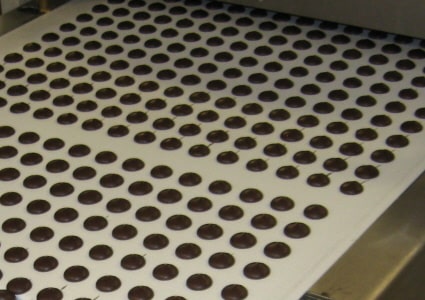

Slider Bed Support (low friction)

Slider bed supports are constructed with hard, smooth, wear-resistant material, such as hardwood, hard plastic or steel. The latter material is most commonly used, the upper side of a flanged, sheet steel frame forming the support. This type of support is used where a smooth conveyance is essential, for example for small, light or fragile items.

All our belts with bare fabric, impregnated back side and fine square pyramid profile can be used on flat slider beds.

Curved Conveying

Conveying goods around corners can be necessary for saving floor space, changing the direction of goods or for sorting purposes.

Curved belts are used to change the transportation direction (between 30 and 180 degrees) or to cope with height differences.

Inclined / Declined Conveying

In inclined conveying measures must be taken to prevent goods from sliding down or falling.

If a higher friction between the piece goods and the belt is necessary, profiling the belt cover is a solution.

For larger angles of inclination or for bulk products, accessories can be fitted onto the belt such as cleats.

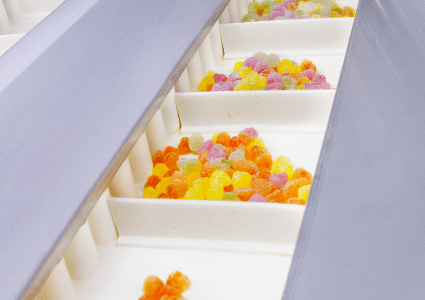

Accumulation

Sometimes it is necessary to interrupt the flow of goods temporarily (for example with a feeding to packing machine).

The simplest solution is to stop the belt, but often this is neither possible nor desirable. In this case, the flow of goods is blocked, while the belt continues to run. This is called accumulation or buffering.

The belt must then have a smooth and wear-free surface, with a low coefficient of friction between belt and product.