Belt Features

Synthetic Belts are produced using different materials, thicknesses, colours etc. Therefore each belt has different features such as high grip, non-fray or wear-resistance for example.

Food Grade belts are primarily used in the Food Industry and the Tobacco Industry. Flame-retardant and energy efficient belts are a sought-after feature in the Airports and Logistics Industries.

Food Grade

For the Food Industry, we offer belts for use in high or low temperatures, with excellent resistance to oils and fats and superb release characteristics.

To ensure food safety and to avoid any food contamination, a complete range of belts is available in compliance with:

- the latest EU regulation EC 1935/2004, EU 10/2011 and amendments

- food contact surface FDA standards

Low Noise, Flame-retardant, Impact Resistant

We offer low noise belts for better working environments capable of high-speed power turns and extremely reliable flame-retardant belts with extra long-wearing top covers.

Our high impact-resistant belts are able to withstand heavy shock loads.

Self-tracking

Working closely with our customers we have option to offer aslo a range of self-tracking belts showing superior performance on fixed centre conveyors, two-way running conveyors and wide, short centre belts. Tracking of a belt in these situations is always very difficult.

- Reduced maintenance costs

- Compact conveyor design

- Less energy consumption

- Easy and quick installation

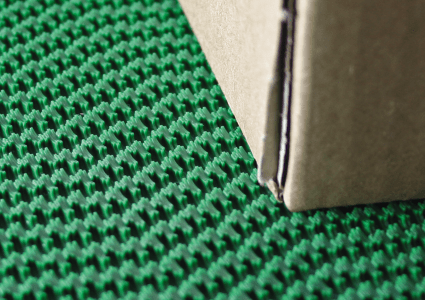

High grip

Our high grip belts are specifically designed to increase the friction between the belt and the products being carried. This is often needed for inclined transport or in slippery conditions.

High grip characteristics can be obtained by using different materials and/or using certain profiles (embossing).

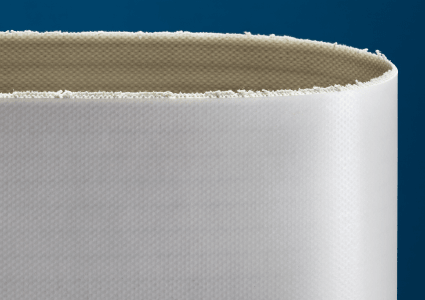

Wear-resistant

We offer a range of wear-resistant belts that are specifically designed to handle even the toughest conditions you can think of.

Wear-resistance is one of the most important properties that determine the life expectancy of a conveyor belt.

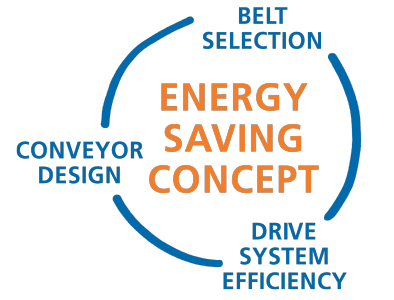

Energy saving

To ensure that belts run as efficiently as possible on conveyor systems, we present a series of belts that offer the potential of a considerable power consumption reduction.

Belt selection is a very important factor in saving energy, but not the only one.

- ‘Energy Saving Concept’ is based on 3 pillars that influence the power demands of a conveyor:

- Conveyor design – in order to get the basics right

- Belt selection – in other words, a fit for purpose belt

- Drum motor sizing – not too big (wastes energy) and not too small (will be overworked)