Standard Materials

The coatings used on Synthetic Belts are called polymers and can be made of various materials which have influence on the suitability of the belt in a certain application.

Polymers can be separated into two different groups: thermoplastic or thermoset.

Mainly used compounds for coatings are:

PVC Belts

Polyvinyl chloride, commonly abbreviated to PVC, is a widely produced plastic. PVC is a type of thermoplastic polymer that is flexible and durable, and therefore suitable for use on conveyor systems.

Main PVC coating types:

Product features:

- Good chemical resistance (including chlorine)

- Hydrolysis resistance (hot water and steam)

- Flame-retardant types available (ISO 340)

- Some food types available (dry food)

- Economically priced

- Available in many different hardnesses, profiles and colours

Industries:

- Airports

- Logistics

- Agriculture

- Fruit and Vegetables

Product features:

- Good resistance to oil and fat

- Food compliance for all foodstuff

- Available in white and light blue, and with different profiles

Industries:

- Food

- Handling unpacked food

Polyurethane Belts

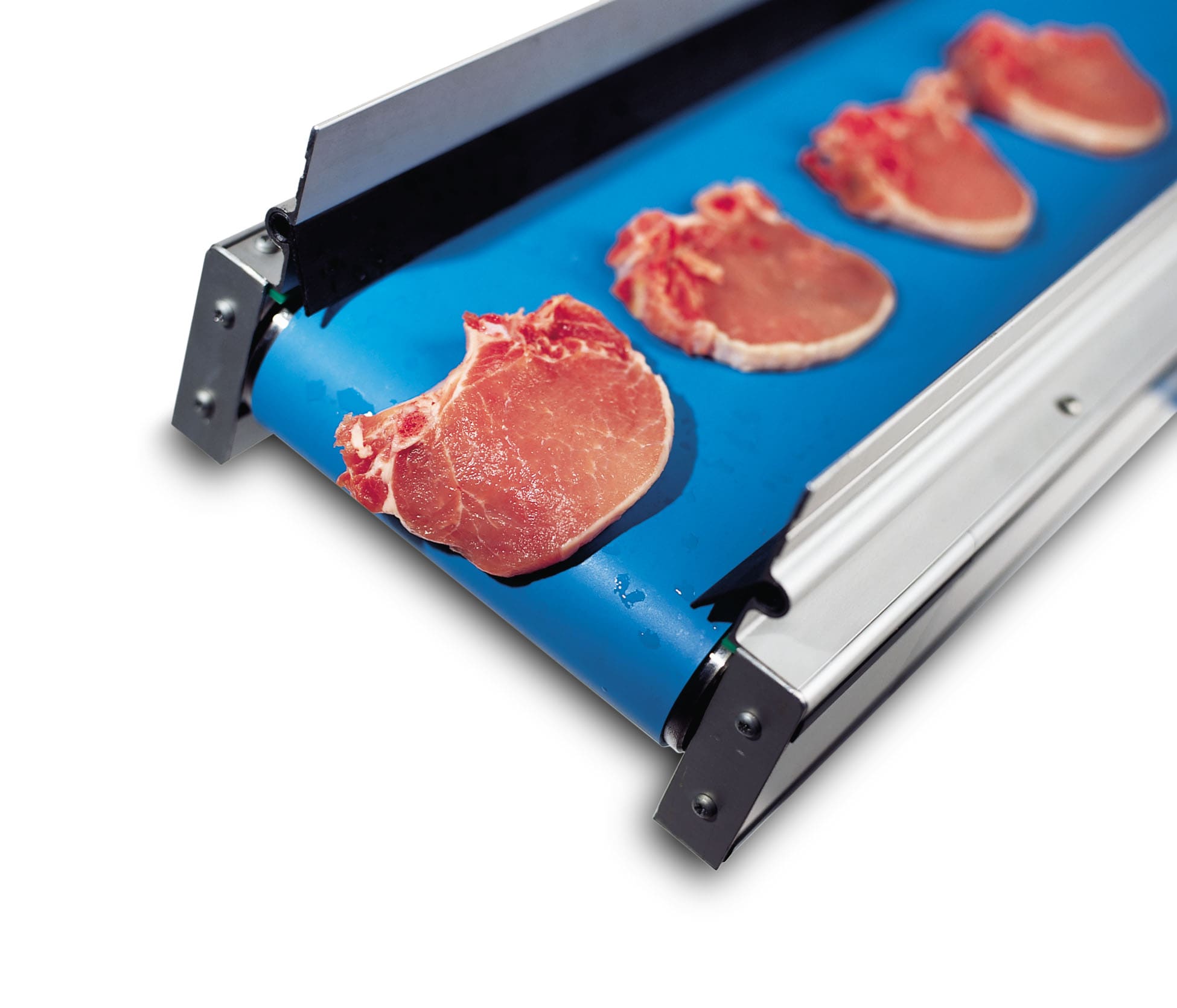

Polyurethane belts are mainly used in the Food Industry. Due to its structure, polyurethane belts do not give off damaging toxins or chemicals. Polyurethanes for process and conveyor belting can be either thermoplastic – TPU, or thermoset – PUR. Thermoplastic polyurethane coating material excels through its exceptional resistance to grease, oils and chemicals.

Main polyurethane coating types:

Product features:

- Belts with thermoplastic polyurethane coating

- Very flexible even at low temperatures

- Very good resistance to oil and fat

- Good abrasion resistance

- Food compliance for all foodstuff

- Available in many colours, and with profiles

- Non-fray

Industries:

- Food

- Packaging

- Wood

- Textile

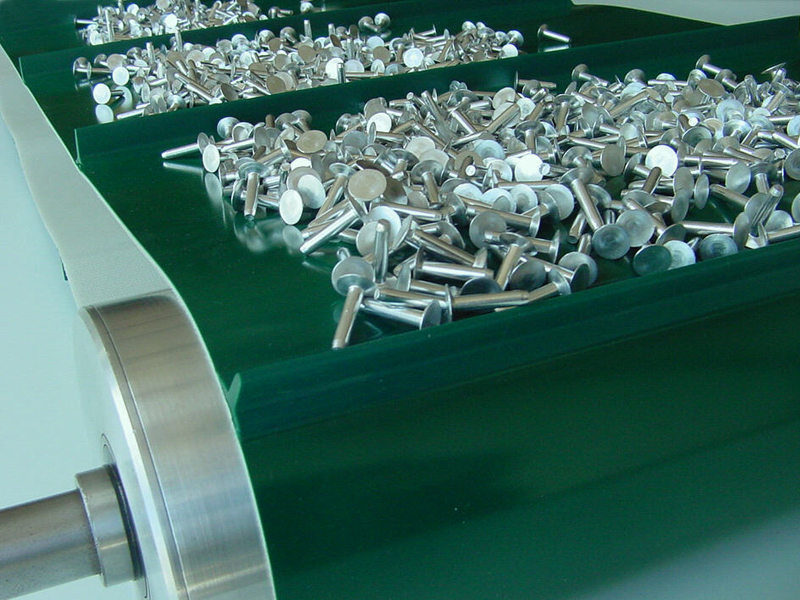

- Metal

Product features:

- Belts with polyurethane impregnation (zero thickness)

- Low friction top side for accumulation

- Very flexible even at low temperatures

- Good abrasion resistance

- Food compliance for all foodstuff

- Available in different colours

Industries:

- Food

- Logistics

- Airport

- Electronics

Polyolefin Belts

Polyolefins are the largest group of thermoplastics; they are polymers of simple olefins such as ethylene. Polyethylene is probably the polymer you see most in daily life; it is the most popular plastic in the world.

- Flexible at low temperatures

- Chemically inert material, good chemical resistance

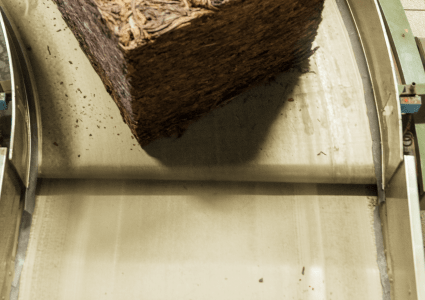

- Pyrolysis resistance (non-toxic when burning, tobacco approved)

- Food compliance

- Easy release properties

- Wide range of types available, with different profiles

- Special types available for small pulley transfer points

- Tobacco

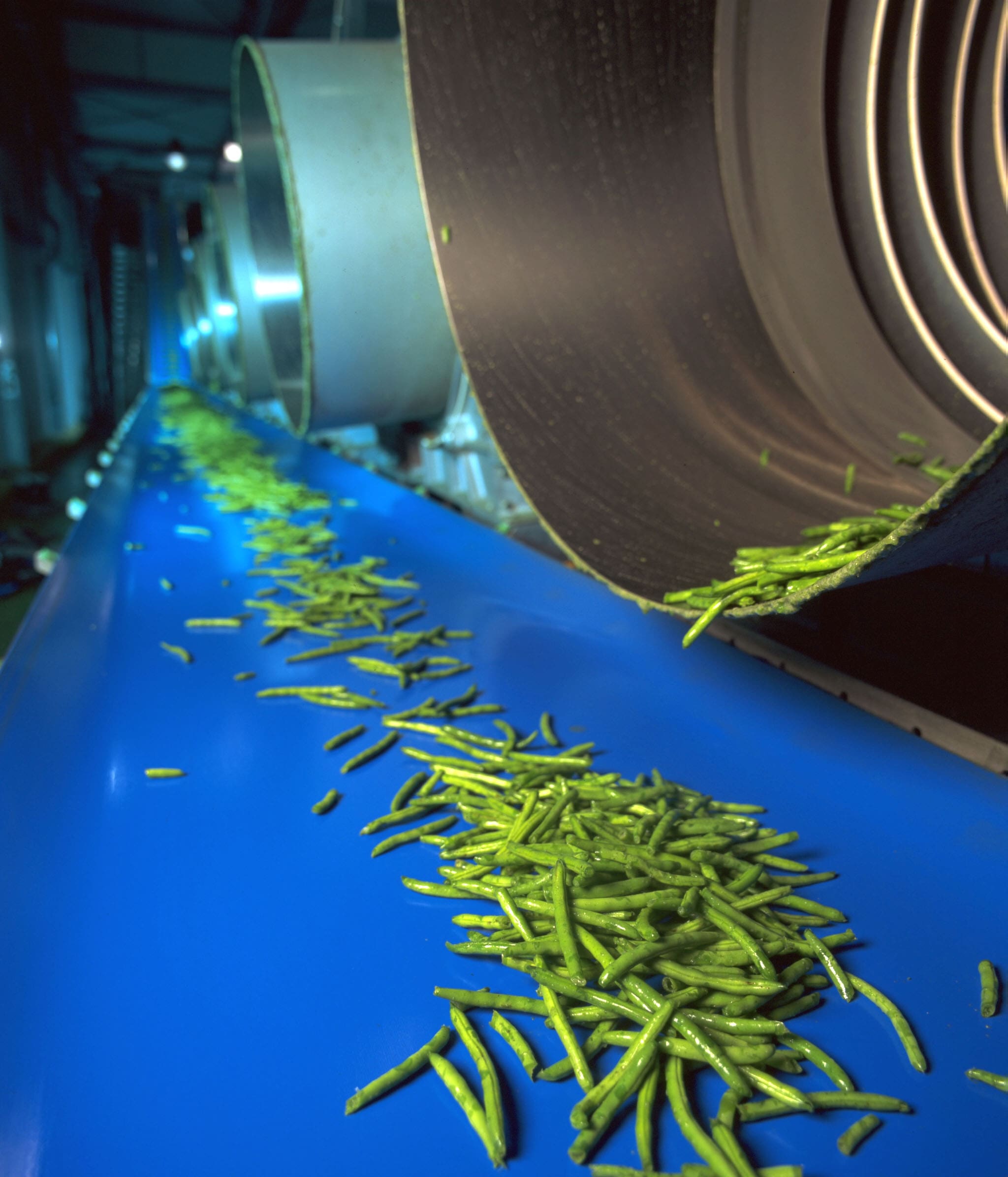

- Food

Polyester Belts

Polyester is a category of polymers that contain the ester functional group in their main chain.

- Polyester

- Mechanically very strong

- Flexible at low temperatures

- Good hydrolysis resistance

- Pyrolysis resistance (non-toxic when burning, tobacco approved)

- Good abrasion and cut resistance

- Tobacco

- Food

Fabric & Felt

Fabric and Felt belts are used in a wide variety of material transport applications such as car manufacturing, food processing and heavy industry. Felt is a non-woven fabric. The most important raw material for belting fabrics is polyester.

- Cotton (natural)

- Flax (natural)

- Polyamide (synthetic)

- Polyester (synthetic)

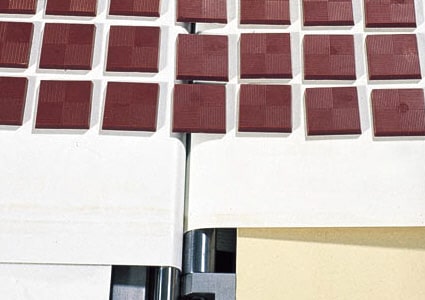

Silicon belts

Silicon belts have good release of sticky product, they are high temperature and chemical resistance.

- Good release of sticky products

- High temperature resistance

- Chemical resistance

- Food

- Tyre

Mixture of Polymers

Mixing PU and PVC polymers together with Rubber.

- High grip

- Good chemical resistance

- Available in different colours

- Very good wear resistance

- Good oil resistance

- Paper and Print

- Wood