Homogeneous Belts

Hygienic and high performance belting solutions

The Belts are manufactured from homogenous Thermoplastic Elastomer (TPE) to give an excellent contact surface for raw, cooked and frozen foodstuffs. Available with textured nonstick or high-grip surfaces.

The belts can be installed on-site to save valuable production time and reduce contamination of the surrounding environment to a minimum.

Homogeneous Belts reduces sanitation time (less changeover time between shifts and more production time), reduces maintenance, reduces water and chemical expenditures and reduces electricity consumption. It lowers bacteria counts for a cleaner, healthier product with improved product shelf life.

- No modules, links, hinges or crevices that harbor bacteria and deposit fragments into the food

- No seams or plies that fray and delaminate; no detachment of flights and guides common plied belts

- Easily cleaned in place in very short time

- Reduced cleaning costs (labor, water, chemicals, wastewater treatment) and downtime

- Reduced loss of food

- Consistent hygiene level over time

- Lower bacteria counts, cleaner product, less investment in conforming to standards, longer product shelf life; suited to HACCP

- Easy to weld or make repairs on site

- Meat & Poultry

- Fish & Seafood

- Vegetable processing

- Bakery & Confectionery

- Dairy

- Recycling

- General Conveying

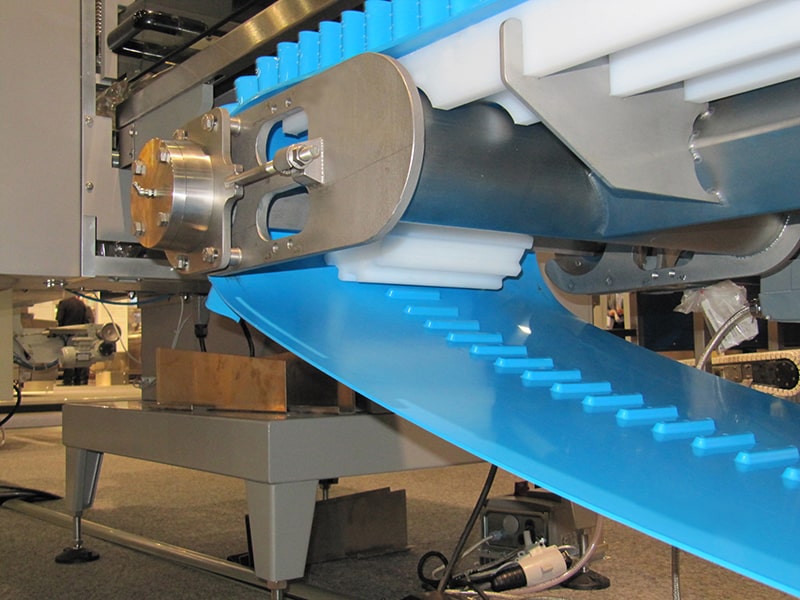

SuperDrive™

SuperDrive conveyor belting reduces sanitation time (less changeover time between shifts and more production time), reduces maintenance, reduces water and chemical expenditures and reduces electricity consumption. It lowers bacteria counts for a cleaner, healthier product with improved product shelf life.

The unique SuperDrive system is installed in thousands of industries and facilities worldwide. In fact, it is the only homogenous positive drive belt with an installation track record of over 10 years of continuous use. SuperDrive™ is considered state of the art for hygiene, quick sanitation and savings in the cost of ownership.

Available in three belt thicknesses (3mm, 4mm or 6mm) and varying hardnesses: food-grade blue and beige (Shore 55D, 53D), a Metal Detectable (MD) version (Shore 53D) and a special Low Temperature (LT) version for deep freeze applications (Shore 95A, 46D).

- Smooth, homogenous surface without crevices prevents bacteria and biofilm buildup

- No ply or edge fraying, compared with fabric belts; no hinges, moving parts and pins, compared with modular belts

- Simple, more hygienic conveyor construction; no heavy friction pulleys

- Reduced product waste

- Works with HACCP systems and standard hygiene/sanitation regimens (CIP)

- USDA/FDA certified EC approved

Schiki Belting SuperDrive system presents a homogeneous Thermoplastic Elastomer (TPE) positive drive conveyor belt with two parallel rows of extruded teeth on the underside of the belting material. The teeth engage in a toothed drive sprocket that drives the belt with little or no pretensioning to prevent off-tracking.

- Minimal pretension reduces elongation

- Reduces noise level to a minimum

- Lightweight belting cuts back on motor and energy usage

- Easy to install

- Strong base for heat-welded fabrications

- Long operating life

DualDrive™

DualDrive positive drive belts lower the cost of ownership due reduced consumption of water and chemicals, reduced maintenance and sanitation costs and reduced downtime. Lower bacteria counts deliver a significantly more hygienic product with improved shelf life. Available in two thickness (3mm or 4mm) and varying hardnesses (Shore 55D, 53D): food-grade blue and beige and a special Low Temperature (LT) version for deep freeze applications (Shore 95A, 46D).

- Smooth and textured belt surfaces

- No fraying, delamination or detaching of flights, compared with coated plied belts

- No fragmenting or chipping, compared with modular belts

- No crevices or links that harbor bacteria

- Easily and effectively cleaned

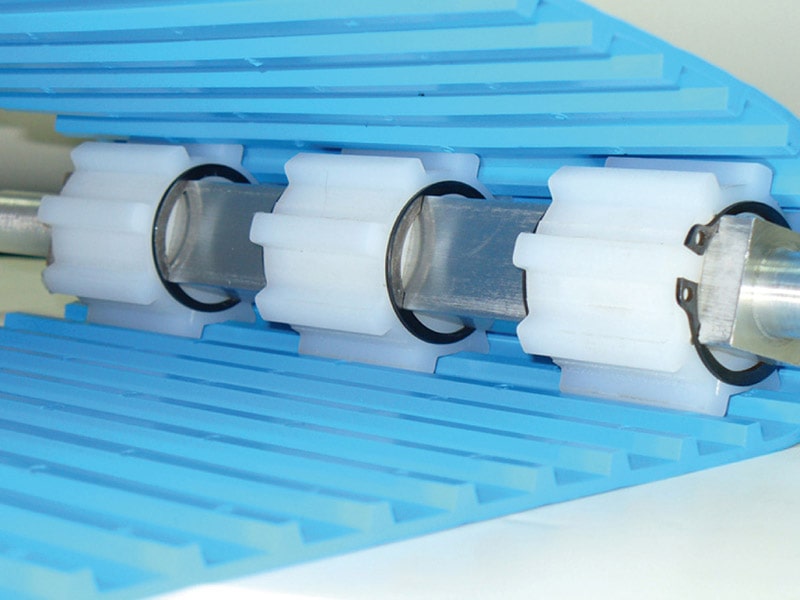

The DualDrive conveyor belt is a positive drive conveyor belt with a series of teeth extruded at a pitch of 50mm and 20 mm across the entire width of the underside. The teeth engage in a toothed drive sprocket that drives the conveyor belt with little or no pretensioning. DualDrive belts replace 2” pitch modular belts with minimal retrofitting.

Soliflex PRO

Soliflex PRO is a positive drive belt, driven by a lug and sprocket system. This system reduces the energy required to run your conveyor and at the same time delivers ultimate tracking; thus virtually maintenance-free.

- Highest hygiene level

- Optimised production throughput

- Reduced operational costs

- Proven technology

- Complies with international Food Grade standards

- Supports your HACCP

- Easy and fast cleaning (uses less water, detergent and time)

- Bi-directional belt with easy on-site splicing

- Excellent product release properties

- Scraper friendly

- Variable custom lug positioning