Extra Wide Timing Belts

Our Extra Wide polyurethane belts (width up to 500 mm) offer the advantages of synchronous timing belts in typical applications of the conveyor belts and plastic modular belts.

Made of polyurethane and high resistance aramid tension cords, our Extra-wide Belts provide positive drive and synchronous conveying.

Advantages:

• no slippage even when used in applications with presence of oils or grease;

• positioning accuracy even at high linear speed;

• very low noise compared to applications with plastic modular belts;

• smaller drive pulley requirements;

• energy saving as a result of low-tension and low friction forces in effect.

The Schiki Belting Extra-Wide polyurethane belts are available open end or welded, coated with materials that optimize conveying, with cleats and special mechanical machining.

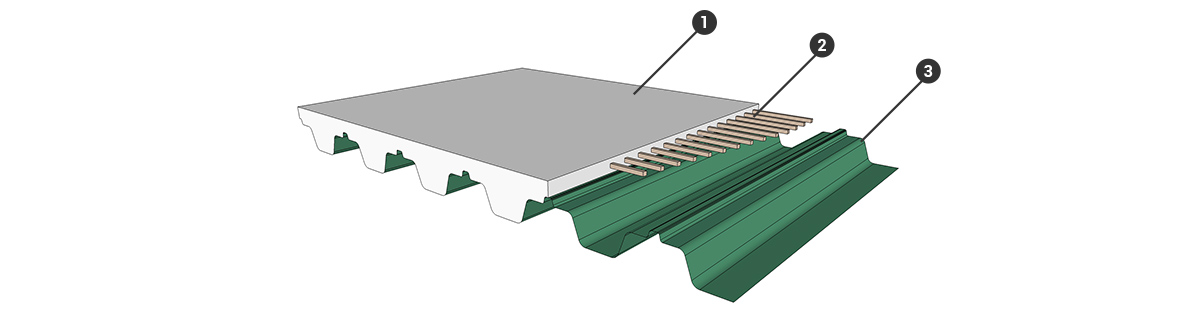

Belt structure

1.) Body thermoplastic polyurethane 92 ° Sh.A high wear resistance.

2.) The traction element is made of aramid fiber cords with high resistance and high elastic modulus.

3.) Fabric on teeth PAZ, PAR on the back or PAZ-PAR (on back and teeth), to reduce the coefficient of friction, improve the tooth engagement and reduce the noise.

Mechanical and chemical properties, product characteristics:

- Transparent color

- Long lasting life

- No cexposed cords on belt edges

- Excellent lenght stability

- Minumum tension decay

- High precision linear and angular positioning

- Silent operations

- Maintenance free

- High resistance to tear and abrasion

- High resistance to aging, hydrolysis and ozone

- Working temperatures between -25°C to +80°C

- High resistance to oils, greases, lubricants and fuels

- Good resistance to acids and alkalis

- Polyurethane for food contact, FDA

- PAZ / PAR fabric to decrease the friction on sliding surfaces

- With self tracking guide

- Coatings in silicone, TPU, PVC and rubber

- Wide range of cleats

- Perforation by high precision water-jet cutting technology

- Production lines for diapers

- Production lines for hygiene products

- Equipment for tire manufacturing

- Transport systems in the food industry

- Tobacco, steel, wood, glass industry

- Transportation and packaging industry

- T10

- H